We shipp to all the world

You can get our machine either through air or sea.

Up to 10% off the bill

Contact us to know more about our special offers.After service

Our team will follow you until you master the machineManuals

With the training we provide you manuals supported with videosstainless steel tray sealer cup filling and sealing machine snake tray sealer

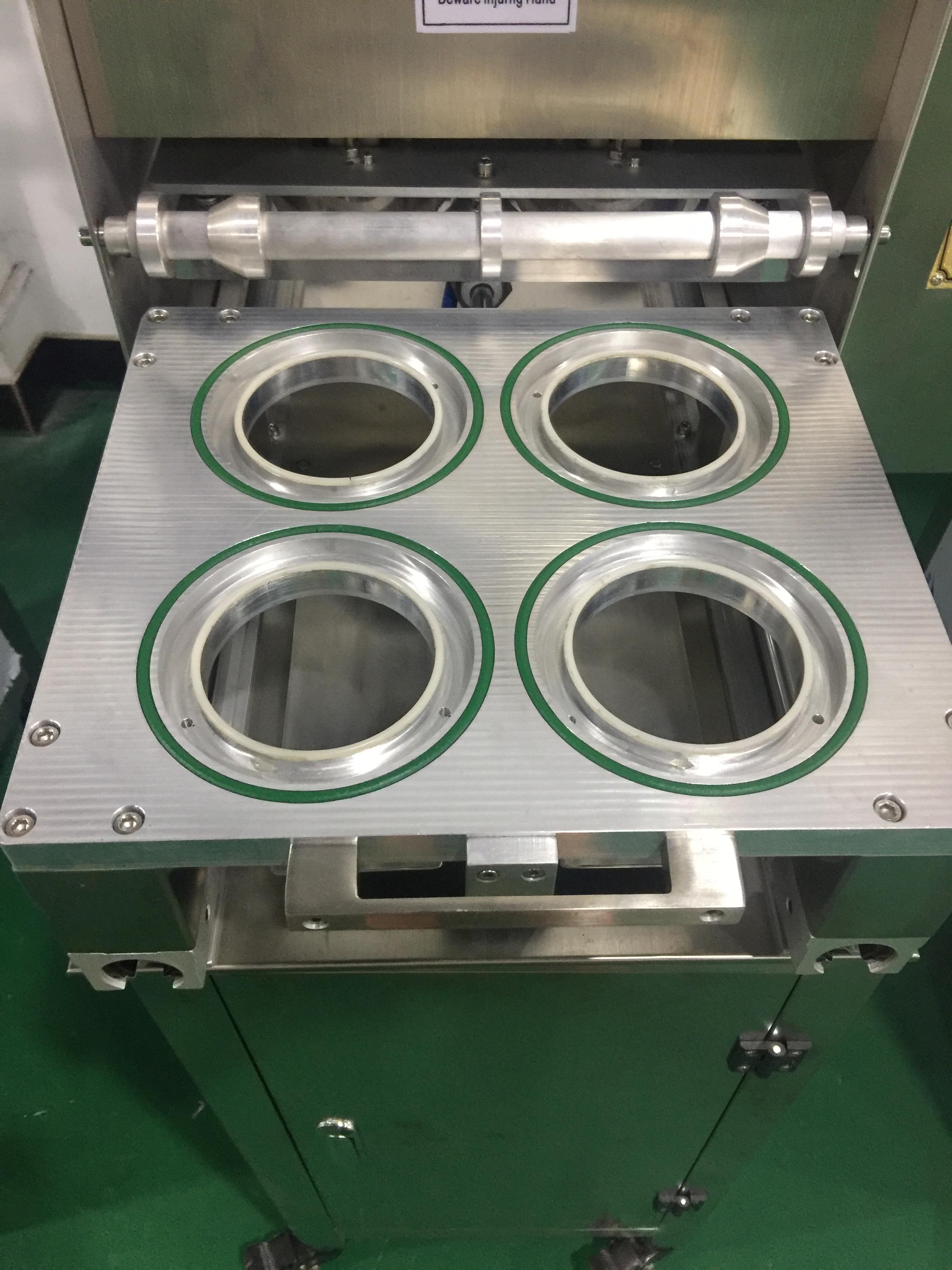

The machine uses non-standard customerizing including but not limited to rectangles, squares, circles, PP,PE and special shapes. heat sealing mould customized according to the actual size of the container, body frame coated with high quality SS304, beautiful and firm, intelligent PLC control system, automatic easy operation, widely used in all kinds of material..

Description

stainless steel tray sealer cup filling and sealing machine snake tray sealer

The machine uses non-standard customerizing including but not limited to rectangles, squares, circles, PP,PE and special shapes. heat sealing mould customized according to the actual size of the container, body frame coated with high quality SS304, beautiful and firm, intelligent PLC control system, automatic easy operation, widely used in all kinds of material..

specification

power: 220v/110v 500-1000w

printer: ribbon printer

system: PLC controller

sealing material: Aluminum/PP/PE/PE etc.

Temperature range: 0-300degree

sealing mouth: 1-4 molds

sealing cup: cup/tray/bowl

diameter: 20-250mm

capacity: 600-1200pcs/hour

machine body: 304 stainless steel

Related Products

-

MZH-PM hot sale high quality perfume glass bottles filling machine with four heads

Product Description:

MZH-FP perfume spray filling machine is the latest Liquid Water filling machine .under each filling nozzle there have a sensor.When the bottle ready put at filling nozzle then filling.More stable and convenience.

1.Performance Introduction:

1.) MZH-FP perfume spray filling machine adopt fully pneumatic control so it is very suitable for the filling of high foam materials and different capacity of containers.2.) The design concept is: through increase pressure on the filling head, vacuum generator achieve a partial sealing environment in the reflow liquid bottle and filling container. Thus generate a partial vacuum(negative pressure) through vacuum suction to achieve filling process.

2.Instruction

This machine is specially used for the sealing of all types of liquid water bottles which after sealing they can keep good sealing performance even under the inclement environment. The work system and control system of this machine adopt pneumatic.Quick View -

Factory price 2019 Guangzhou egg printing machine date coding cosmetic package machine

Description:

Inkjet printer to print dates and batch numbers ,Inkjet of the information content can be freely edited,in the product surface continuous,non-contact and jet printing.

Inkjet printer to print dates and batch numbers has an excellent adhesive for many types of materials such as film, glass, metal, plastic, paper and so on. There are a variety of dot matrix fonts: 5 * 8,8 * 8,12 * 8,12 * 8,16 * 16,16 * 16,24 * 24 and the corresponding bold, all kinds of fonts can be mixed in a message .

Inkjet printer to print dates and batch numbers through the membrane keyboard control, WYSIWYG software, user-friendly, easy to operate.

Inkjet printer to print dates and batch numbers based optimized design and rigorous testing, using a perfect match with each other accessories. Is easy to operate jet printing can achieve the best quality, performance, stability and the greatest degree of safety.

Quick View -

MZH-V high quality emulsifier mixer for cosmetics ointment soap shampoo making vacuum emulsifying mixing machine

-

External circulation vacuum Emulsifying mixer

USAGE & APPLICATION FIELD

The product is mainly applied in such industries as daily chemical care products, biopharmaceutical industry, food industry, paint and ink, nanometer materials, petrochemical industry, printing and dyeing auxiliaries, pulp & paper, pesticide, fertilizer, plastic & rubber, electrics and electronics, fine chemical industry, etc. The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

Download the description file: pdf format

Quick View -

MZH-VT VACUUM EMULSIFYING MIXER(UP-HOMOGENIZER)

1 volume volume whole volume: 1300 L

2 volume body use volume: 1000 L

3 minimum production 300L

4 standard size: 3870 * 3800 x 3100mm/4650mm

5 total net weight: 6300kg, host weight: 3500kg

6 Volume: vertical forward flange connection, equipped with double jacket.

7 steam heating: double jacket cooling with indirect system: cold water.

8 volume body: atmospheric state / vacuum.

9 body base: welded, high mirror polishing.

10 cover: flange connection, can be lifted.

Quick View

What we are about

We are a new high-tech company with a combination of design, manufacture, consultation and sale. Taking advantage of the professional standards and mechanical Engineering mellow technology in the field of chemical machinery, Now, This company is making great progress..

Follow us on:

Reviews

There are no reviews yet.