Washing Soap Liquid Detergent Making Machine with Mixing and Heating

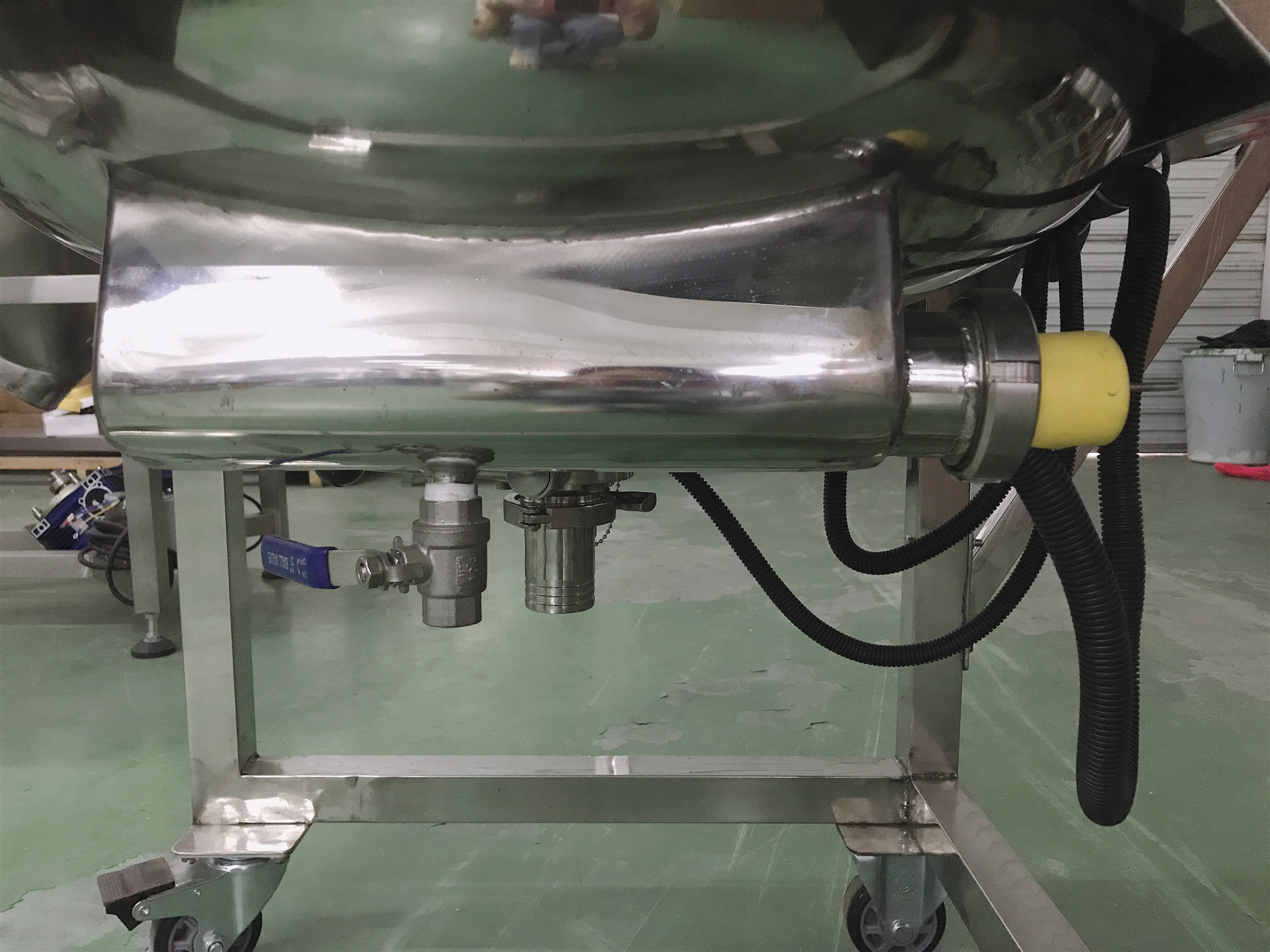

1. Made of imported SUS304 (sus316l can be customed ), The tank body and pipe are subjected to mirror polishing.

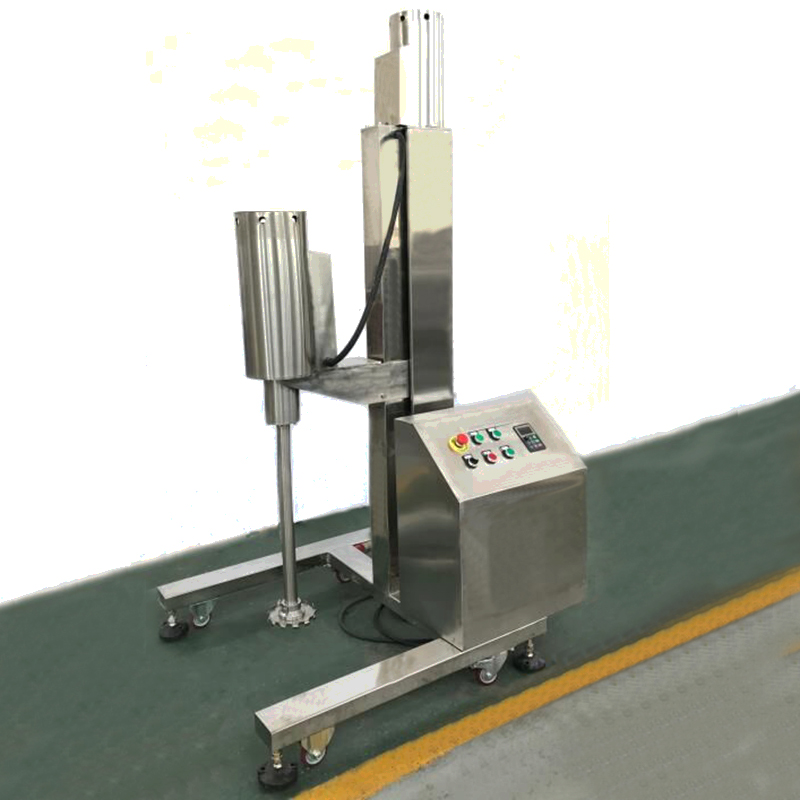

2. The stainless steel electric control cabinet can completely supervise the operation of equipment, and display such data as temperature and blending rotation speed etc.

Description

Washing Soap Liquid Detergent Making Machine with Mixing and Heating

How the mixing tank works

A driving device (motor or reducer) is arranged on the cover of the stirring tank, and the stirrer in the stirring tank is driven by a driving shaft.Shaft sealing device can be used in mechanical seal or packing, labyrinth seal and other forms (according to user needs).

Applicable Products:

1. Cosmetics industry: skin care cream, shaving cream, shampoo, toothpaste, cold cream, cold sun cream, facial cleanser, nutrition dense, detergent, shampoo, hair cream, conditioner, serum, moisturizing cream, Hand cream and so on.

2 Daily chemical industry:

Laundry liquid production, hand sanitizer, toilet net, car glass water.

3. Pharmaceutical Industry:

Latex, emulsion, ointment (ointment), oral syrup, oral liquid and the like.

4. Food Industry:

Sauces, cheese, nutritional liquid, baby food, chocolate, sugar and so on.

5. Chemical Industry:

Latex, Sauce, saponified products, paints, coatings, resins, adhesives, lubricants and so on.

Parameter:

1. Material: Inner: SUS316L Thickness:6mm

Middle: SUS 304 Thickness: 6mm

Outer layer: SUS304 Thickness: 3mm

2. The actual volume: 1200L

Work volume:1000L

3. Mixing speed: 0-63r / min (frequency control); motor power: 4KW

Scraper for the overall manufacture of PTFE; imported reducer

Under the homogeneous speed: 0-3000r / min (frequency control); Power: 7.5KW

4. Heating method: electric heating

Whole pot heating time: 1-2 hours

5. With ladder, operating platform, electric control cabinet. SUS304 stainless steel stent embossed aluminum, wash water all through the pipe into the outfall

Reviews

There are no reviews yet.