Description

MZH-F Liquid and paste manual filling machine

Usage

This manual filling machine can filling lotion,jar,cream,ointment,shampoo ect. This unit adopts piston-structure which can fill liquid and ointment materials with the quota of 5-60g. The structure is compact, easy to operate, accurate measurement, all the parts which contact materials adopt stainless steel and polytetrafluoroethylene, with wear and corrosion-resistant features, especially suitable for the filling of small amount of materials in medium or small size enterprise, hospital, laboratory, etc. This product has already been approved by the national outward appearance patent and use of products patent and the counterfeit will be went behind.

II. Technical Parameter

filling range: 5-60ML capacity of the hopper:15L

total weight: 13kg shape dimension:270×270×700mm

MZH-FH Heating mixing and filling machine

This heating mixing filling machine can be used in food, cosmetics, medicine, chemical and beverage industries, such as soy sauce, seasoning, gelatin, grease and cream. The material contact part is made of stainless steel, which is clean, sanitary, easy to wash and wash, accurate in measurement and simple in operation. It is widely used in small businesses and individual users.

All the parts of this machine are made of stainless steel, which have anti – embroidery and corrosion resistance. Such as toothpaste, ointment, bald, juice, jam, shoe oil, paint, ink, drink, paste, snow, cold cream, milk, butter, oil, wine, agricultural medicine, PS plate paste and other materials.

Product features:

◆This machine adopts imported components with excellent quality, and piston and cylinder are made of stainless steel and polytetrafluoroethylene.

◆The excellent imported components and excellent mechanical design guarantee their absolute leading position in similar products in China.

◆New horizontal design, light and convenient, automatic material extraction, avoid the trouble of frequent feeding of vertical hopper.

◆Manual and automatic mutual switching function, when the machine is in “automatic” state, the machine will continue filling automatically according to the set speed. And the machine is in the “hand movement” state, the operator step on the pedal to achieve filling, if it has been kept on, then into the state of automatic continuous filling.

◆Material cylinder, the three part part is handcuffed, easy to assemble and disassemble, without any special tools. It is very convenient to clean.

◆The anti dripping filling system fills the cylinder up and down and fills the head when filling. The cylinder down, then the head downwards, that is, the valve opens, starts filling material, the cylinder upwards, then the head upwards, the valve closes, stops filling, and eliminates the occurrence of drip and wire drawing.

Machine Description

This hot filling machine is suitable to measurably fill the ointment materials with high viscosity and poor flow ability.It does the filling pneumatically, its hopper and the cylinder both are thermally preserved with electrically heated circulating water.The hopper is equipped with a frame mixing system.The machine is easy to clean and operate,conforming to GMP standards.

Pneumatic parts adopt Taiwan Airtac brand piston and Japan SMC. Piston of cylinder and material jar adopt tetrafluoroethylene and 316L stainless steel. Filling volume and filling speed can be controlled, high filling precision.

| Model | MZH-F5-60ML |

| Mixing power | 220V 0.09(kw) |

| Raw water pump power | 220V 0.18(kw) |

| Heating power | 4.5 (kw) |

| Filling volume | 5-60ml 10-120ml 25-250ml 50-500ml

(can be adjusted as customer request) |

| Filling mouth | 1 |

| Dimension | 650×580×2100(mm) |

| Bottle height | adjustable(mm) |

| Bottle diameter | adjustable(mm) |

| Capacity | 20-40bot/min |

| Filling precision | ±0.5% |

| Air source pressure | 0.8Mpa |

| Working pressure | 0.6 Mpa≦ |

MZH-FW Semi automatic Horizontal Pneumatic liquid and paste Filling Machine

Working principle of Horizontal paste filling machine:

This machine adopts a piston type push rod structure, and produces strong pushing force from the cylinder to drive the piston head. When the main cylinder goes back to live plug head, the valve is opened, the outlet valve is closed, and the material will be sucked into the material cylinder because of the pressure difference in the material cylinder. This is the stroke of the material. After the suction stroke is completed, the main cylinder will push the piston head outwards. At this time, the inlet port valve is closed and the discharge port valve opens. The material is pushed out of the cylinder by the piston mouth. Filling through the discharge port to the container is the filling stroke.

Pneumatic paste filling machine description:

Semi automatic pneumatic paste liquid filling machine is paste and liquid filling equipment. This type of equipment is designed and upgraded in depth with reference to the advanced filling technology at home and abroad. The new horizontal flat design is light and convenient. The equipment adopts pneumatic parts (cylinder) and piston type push rod structure, because the vacuum chamber can be formed in the material cylinder, and the material is suck at negative pressure. Therefore, it can be filled with viscous, poor fluidity materials.

The characteristics of the horizontal filling machine:

- Material contact parts are made of 316L or 304 stainless steel. Meet the requirements of GMP

2, the whole machine uses compressed air as a power source, for the use of power, no collision and hard friction in the operation of the machine, so it is suitable for use in an occasion with anti riot requirements, with higher safety.

- Adopting fixed volume metering and piston type push rod structure, the equipment has high filling accuracy and small error (less than 1%).

4, there is a filling control handle, filling speed can be adjusted arbitrarily, filling accuracy is high.

5, with automatic absorption, quantitative filling, uniform discharge, emergency shutdown, filling capacity and speed can be arbitrary adjustment functions.

- The filling head adopts cylinder valve or mechanical valve, and the head of the filling head is provided with anti dripping plugging head to prevent the drawing head from drawing and dropping.

- The components are connected by clamps to facilitate assembly disassembly, cleaning, maintenance and assembly.

- Machine set (manual) and (automatic). (manual) through pedal control filling, (automatic) machine continuous filling.

| Name | Horizontal Pneumatic filling machine |

| Model | 500-5000ml |

| Article | Cream or Lotion |

| Volume | 5-60ml 10-120ml 25-250ml 50-500ml 100-1000ml 250-2500ml 500-5000ml |

| Filling | Piston filling |

| Precision | ±0.5% |

| Pneumatic | 0.6-0.8Mpa |

| Caliber | ≥¢5mm |

| Capacity | 20-60 times/min |

| G.W. | 80Kg. |

| Dimension | L750*W550*H850mm |

| Function | This is a Full pneumatic filling machine for Food,Cosmetic and Pharmacy products.

It can fill food material as Oil,Liquids sauce,Ketchup,Honey,Salad dressing,Soybean. It can fill Cosmetic material as Paste,Skin care,Shampoo, Lotion,Shower,Cream.etc. It can fill Pharmacy material as Ointment,Disinfectant fluid,Cough syrup,other liquid medicine. |

| Remarks | The machine can be autometic or manual that if you want to filling by automatioc you should adjust filling gram.when it filling at the right gram then filling .The speed can adjust.If filling by manual that you should step the pedal of the machine.steping one time is once filling. |

MZH-FW Semi automatic Horizontal Pneumatic liquid and paste Filling Machine

Working principle of Horizontal paste filling machine:

This machine adopts a piston type push rod structure, and produces strong pushing force from the cylinder to drive the piston head. When the main cylinder goes back to live plug head, the valve is opened, the outlet valve is closed, and the material will be sucked into the material cylinder because of the pressure difference in the material cylinder. This is the stroke of the material. After the suction stroke is completed, the main cylinder will push the piston head outwards. At this time, the inlet port valve is closed and the discharge port valve opens. The material is pushed out of the cylinder by the piston mouth. Filling through the discharge port to the container is the filling stroke.

Pneumatic paste filling machine description:

Semi automatic pneumatic paste liquid filling machine is paste and liquid filling equipment. This type of equipment is designed and upgraded in depth with reference to the advanced filling technology at home and abroad. The new horizontal flat design is light and convenient. The equipment adopts pneumatic parts (cylinder) and piston type push rod structure, because the vacuum chamber can be formed in the material cylinder, and the material is suck at negative pressure. Therefore, it can be filled with viscous, poor fluidity materials.

The characteristics of the horizontal filling machine:

- Material contact parts are made of 316L or 304 stainless steel. Meet the requirements of GMP

2, the whole machine uses compressed air as a power source, for the use of power, no collision and hard friction in the operation of the machine, so it is suitable for use in an occasion with anti riot requirements, with higher safety.

- Adopting fixed volume metering and piston type push rod structure, the equipment has high filling accuracy and small error (less than 1%).

4, there is a filling control handle, filling speed can be adjusted arbitrarily, filling accuracy is high.

5, with automatic absorption, quantitative filling, uniform discharge, emergency shutdown, filling capacity and speed can be arbitrary adjustment functions.

- The filling head adopts cylinder valve or mechanical valve, and the head of the filling head is provided with anti dripping plugging head to prevent the drawing head from drawing and dropping.

- The components are connected by clamps to facilitate assembly disassembly, cleaning, maintenance and assembly.

- Machine set (manual) and (automatic). (manual) through pedal control filling, (automatic) machine continuous filling.

| Name | Horizontal Pneumatic filling machine |

| Model | 500-5000ml |

| Article | Cream or Lotion |

| Volume | 5-60ml 10-120ml 25-250ml 50-500ml 100-1000ml 250-2500ml 500-5000ml |

| Filling | Piston filling |

| Precision | ±0.5% |

| Pneumatic | 0.6-0.8Mpa |

| Caliber | ≥¢5mm |

| Capacity | 20-60 times/min |

| G.W. | 80Kg. |

| Dimension | L750*W550*H850mm |

| Function | This is a Full pneumatic filling machine for Food,Cosmetic and Pharmacy products.

It can fill food material as Oil,Liquids sauce,Ketchup,Honey,Salad dressing,Soybean. It can fill Cosmetic material as Paste,Skin care,Shampoo, Lotion,Shower,Cream.etc. It can fill Pharmacy material as Ointment,Disinfectant fluid,Cough syrup,other liquid medicine. |

| Remarks | The machine can be autometic or manual that if you want to filling by automatioc you should adjust filling gram.when it filling at the right gram then filling .The speed can adjust.If filling by manual that you should step the pedal of the machine.steping one time is once filling. |

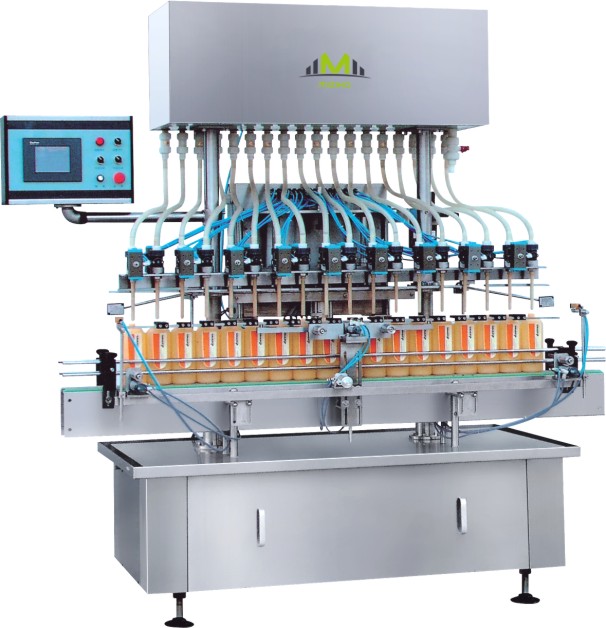

MZH-PLC-Controlled Semi-auto Fluid liuid Filling Machine

- Features

- With a PLC for filling control and Variable-frequency drive control technology independently developed by us, the machine is accurate in filling volume control and easy to operate.

- The touch screen with buttons is easy to operate with high sensitivity and chip memory functions.

- The stainless steel 316L gear pump used features good corrosion resistance, reliable quality and long service life.

- The machine is simple to clean and easy to maintain. 304 stainless steel exterior.

- The machine is capable of filling most types of fluids from a filling volume of 5ml to 10000ml, which is easily adjustable.

The compact and multifunctional machine may be automatically or manually operated and used in a production line.

- Scope of Applications

- For filling of foods, medicines, cosmetics, oils, daily chemicals and other particle-free fluids.

For filling of all kinds of round, square and special-shaped bottles with liquids

III. Technical Data

| Items | MZH-1(Single pump) | MZH-2(Double pump) |

| Power supply | AC220V 50/60Hz 38W | AC220V 50/60Hz (38×2)W |

| Dimensions of mainframe | 410×330×270mm | 510×330×270mm |

| Packing size | 525×445×345mm | 610×480×385mm |

| Error | ≤-0.5%~+1.5% | |

| Weight | 11㎏ | 16㎏ |

| Maximum flow/single pump | ≥1.4(L/min) | ≥1.4(L/min)×2 |

| Model | MZH-F4 |

| Air Pressure | >0.7MPa |

| Pressure of Reducing Valve | 0.55-0.65MPa |

| Air Consumption | 0.3 m3/min |

| Capacity | 20-40 time/min |

| Filling Range | 10-1500ml |

| Precision | ±1.5g |

| Power consumption | 0.55KW |

| Use bottle heigh | 250mm (customized) |

Reviews

There are no reviews yet.