We shipp to all the world

You can get our machine either through air or sea.

Up to 10% off the bill

Contact us to know more about our special offers.After service

Our team will follow you until you master the machineManuals

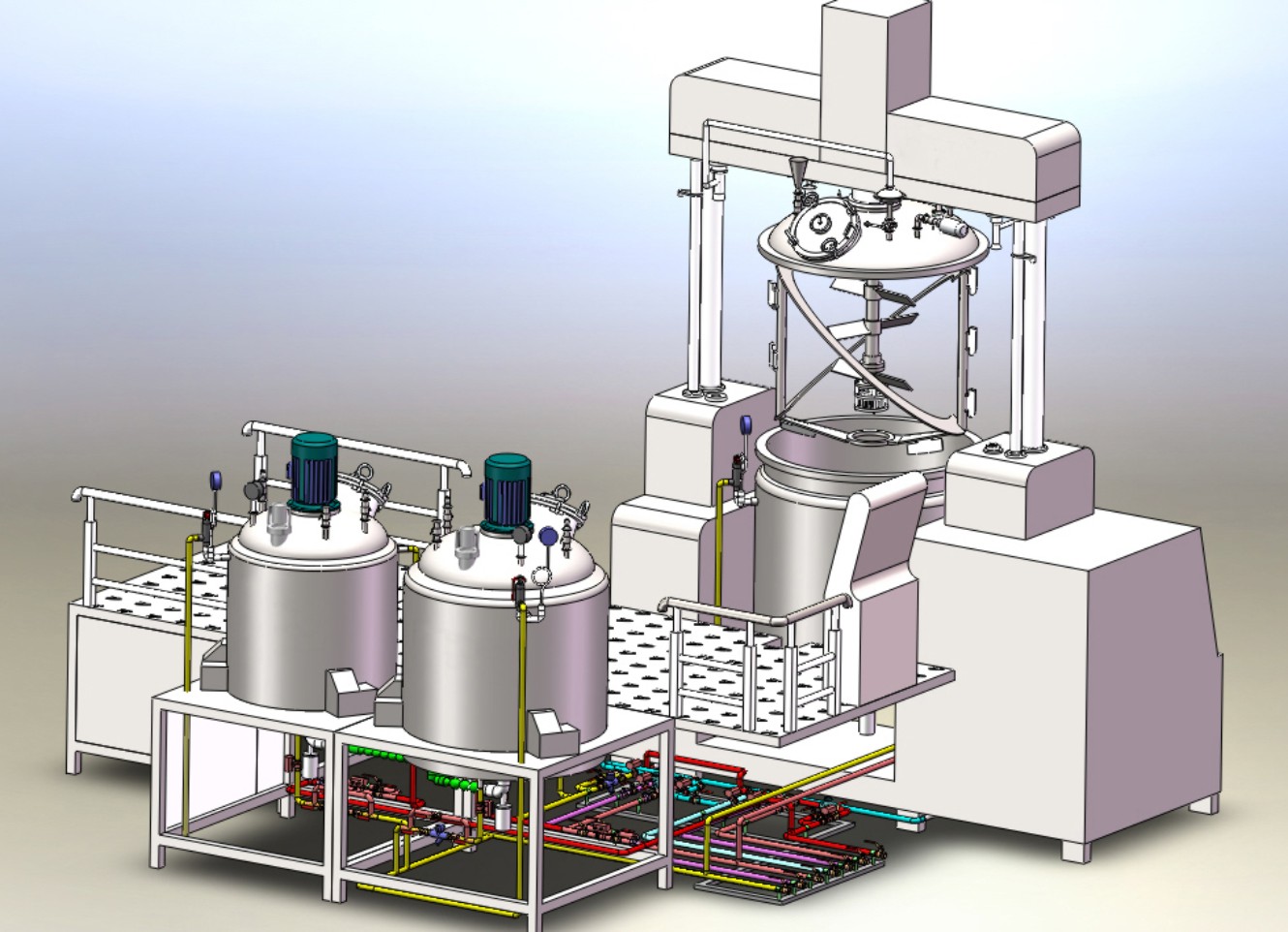

With the training we provide you manuals supported with videosMZH-VT VACUUM EMULSIFYING MIXER(UP-HOMOGENIZER)

1 volume volume whole volume: 1300 L

2 volume body use volume: 1000 L

3 minimum production 300L

4 standard size: 3870 * 3800 x 3100mm/4650mm

5 total net weight: 6300kg, host weight: 3500kg

6 Volume: vertical forward flange connection, equipped with double jacket.

7 steam heating: double jacket cooling with indirect system: cold water.

8 volume body: atmospheric state / vacuum.

9 body base: welded, high mirror polishing.

10 cover: flange connection, can be lifted.

Description

MZH-VT VACUUM EMULSIFYING MIXER(UP-HOMOGENIZER)

PERFORMANCES & FEATURES

◆For materials of super high viscosity (above 50,000C.P.S), recommends the use of corresponding high viscosity emulsifying homogenizer.

◆Raw materials can be directly sucked into the groove by the machine.

◆The machine is provided with vacuum, hydraulic pressure, heating, cooling and other functions.

◆Emulsifying, blending and dispersion can be completed within a short period of time.

◆Slow speed blade type blending and high speed homogenizing systems are provided with frequency conversion control.

◆Users can select pushbutton control or PLC touch screen system.

◆Parts that contact materials are made of stainless steel SS316L. The whole equipment conforms to GMP standard.

◆Blending is carried out under vacuum to effectively ensure the emulsifying effect.

◆The equipment is provided with the CIP cleaning device, which can conveniently use the self-contained CIP cleaning system of users to clean the equipment.

Device description

The MZH-VT emulsifier is a kind of three coaxial mixing mixers. It is suitable for stable homogeneous emulsification. The produced material is very small. The quality of the emulsification depends on how the particles are dispersed during the preparation stage. The smaller the particles, the weaker the tendency to aggregate onto the surface, thus the smaller the chance of emulsification. Depending on the mixing action of the reverse blade, the homogenizer obtains high quality emulsion mixing effect under the vacuum treatment condition.

The MZH-VT turbine emulsifier has good performance in guaranteeing the high quality of the final product.

Product introduction

The MZH-VT-10L-1000L type vacuum emulsifier is an imported advanced technology, which is specially designed according to the ointment technology of cosmetics and ointment products. It is composed of emulsified mixing pot, vacuum system, hydraulic system and electrical control system.

Basic configuration and technical parameters of the whole machine

The whole system consists of emulsification stirring pot, vacuum system, double cylinder oil column hydraulic system and electrical appliance control system.

Emulsified agitator:

Working volume 1000L, material SUS316L stainless steel, electric heating / steam heating, water cooling two.

There are three sets of agitator in the pot.

Shear jet emulsification mixer, power 15KW speed 0 – 3500r/min, (frequency conversion timing)

Slow frame scraper mixer, power 4KW speed 0 – 40 r/min? (frequency conversion timing)

Slow reverse mixer, motor and slow scraper mixer for the same motor, (rotate speed is 0-40r/min).

The device attached to the tank: the liquid intake port with stainless steel pipe filter, solid feeding port, vacuum port, compressed air inlet, broken air entrance, view mirror, temperature sensor, CIP cleaning head, outlet, dustproof aseptic breathing device;

Preconditioning cooker (no)

Capacity (Shui Xiangguo) 800L; (oil pan) 600L each one

vacuum system

Use of water ring vacuum pump

Hydraulic system

It includes two cylinder oil cylinder, solenoid valve, overflow valve, fuel tank and pressure retaining valve.

Electrical control system (options)

PLC touch screen control / button control

Whole machine technical parameter

1 volume volume whole volume: 1300 L

2 volume body use volume: 1000 L

3 minimum production 300L

4 standard size: 3870 * 3800 x 3100mm/4650mm

5 total net weight: 6300kg, host weight: 3500kg

6 Volume: vertical forward flange connection, equipped with double jacket.

7 steam heating: double jacket cooling with indirect system: cold water.

8 volume body: atmospheric state / vacuum.

9 body base: welded, high mirror polishing.

10 cover: flange connection, can be lifted.

11 speed of slow mixing system: 0-40 r/min. 4KW (frequency conversion speed)

12 fast homogeneous mixing system speed: 0-3500 r/min. 15KW (frequency conversion timing)

13 vacuum pump installation Power: 4KW.

14 container jacket working pressure: 0.09Mpa

15 total installed power: 29KW (only standard equipment, no other options)

16 power requirements: 380V, 50HZ.

17 allowed voltage fluctuations: + / – 5%.

18 low voltage control: 24V Olts

19 protection: ordinary.

20 water consumption of liquid ring vacuum pump: 6L/ min.

21 rack height adjustable + / – 10.

22 air suction device for a ventilating motor.

23 low voltage security protection (24 volts).

24 equipment manufacturing meets the GMP standard.

25The body is made of all SUS304 stainless steel.

26 all parts contacting with the material are 316L stainless steel and mirror polished.

Related Products

-

MZH-V vacuum homogenizing emulsifying mixer( shampoo, liquid soap, detergent, pesticide…. mixing machine) (Copy)

Quick Details

Quick Details- Condition:New

- Mixer Type:Homogenizer

- Additional Capabilities:Homogenizer mixer

- Max. Loading Capacity:5-5000L, customized

- Voltage:220V/380V 50HZ, 3KW

- Power(W):15-88KW

- Dimension(L*W*H):2920*2120*2200mm

- Certification:SGS/CE/ISO9001

- Effective capacity:100L

- Emulsify:0-3800 R/min

- contact material:SUS316L

- blender:0-63r/m speed adjustable

- additonal capabilities:mixing&emulsifying

- outlet:tilting system

Quick View -

Fixed type homogenizer mixer

-

Ultrasonic plastic bags popsicle packing liquid filling sealing machine

Machine Parameters:

Power supply

220v50Hz pressure 0.6Mpa

The sealing efficiency 20-25 PCS/min

Filling accuracy ±1%

The sealing height 30~220mm(customizable)

Frequency

20KHz

Sealing diameters

15~50mm(customizable)

Power

2KW

Filling range

5-60ML,10-120ML,25-250ML

Dimension

L1300*W900*H1550mm

Weight 350kgs

Machine configuration details :(the following configuration is a standard model, optional according to customer requirements)

Ultrasonic system

HANGSON Digital automatic frequency tracking Benchmarking electric eye

Japan Panasonic PLC

Coolmay

Relay Touch Screen Coolmay

Quick View -

External circulation vacuum Emulsifying mixer

USAGE & APPLICATION FIELD

The product is mainly applied in such industries as daily chemical care products, biopharmaceutical industry, food industry, paint and ink, nanometer materials, petrochemical industry, printing and dyeing auxiliaries, pulp & paper, pesticide, fertilizer, plastic & rubber, electrics and electronics, fine chemical industry, etc. The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

Download the description file: pdf format

Quick View -

MZH-L Semi automatic plane adsorption labeling machine

Scope of application

Applicable labels: stickers, adhesive film, electronic monitoring code, bar code and so on.

Applicable Products: Products that need to be labeled on flat, curved, circumferential, concave, convex or other surfaces

Application Industry: widely used in cosmetics, food, toys, daily chemical, electronics, medicine and other industries.

Examples are: shampoo flat bottle labeling, packing box labeling, bottle cap, plastic shell labeling, etc.

Quick View

What we are about

We are a new high-tech company with a combination of design, manufacture, consultation and sale. Taking advantage of the professional standards and mechanical Engineering mellow technology in the field of chemical machinery, Now, This company is making great progress..

Follow us on:

Reviews

There are no reviews yet.