We shipp to all the world

You can get our machine either through air or sea.

Up to 10% off the bill

Contact us to know more about our special offers.After service

Our team will follow you until you master the machineManuals

With the training we provide you manuals supported with videosLaboratory high shear emulsifier homogenizing mixer

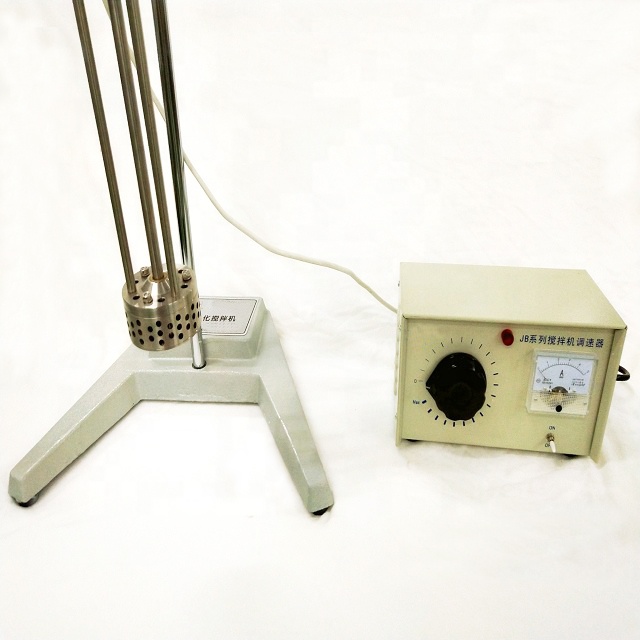

MZH-M type High shear emulsifying mixer, applicable to the biological, physical and chemical, cosmetics, health products and food, and other areas of the experiment.

Description

Laboratory high shear emulsifier homogenizing mixer

Product description:

MZH-M high shear emulsifying mixer is suitable for experiments in the fields of biology, physics and chemistry, cosmetics,

health care products and food, etc.

The product design is novel and advanced, the output power is big, the running speed is fast, the experiment operation is simple.

Features :

1. With special steep slope speed control function, the test speed can be selected at any time within the speed range.

2. The unique structure of shear emulsification ensures that the rotor of the working head rotates at a high speed and the motor drives a high linear speed, resulting in strong fluid shear stress and severe mechanical effects on the frequency.

3. This state may be used for clearance flow to prevent a large number of medium rotation.

4. In a very small space, the performance is very high, and the efficiency is about one thousand times that of ordinary stirring.

5. Under the action of centrifugal force, the experimental materials can shear, tear, impact and mix tens of thousands of times per minute, so as to achieve the effect of shear emulsification.

6. Working head status or configuration of different specifications can meet different experimental needs.

7.Its distinctive features and functions, as well as factories, medical units, biological research, cosmetics, food processing, colleges and universities and other scientific research, product development, quality control and production process of application of the ideal equipment.

Technolgy Specification:

| Power | AC 200V 50Hz |

| Input Power | 5l0W |

| Output Power | 300 W |

| Head Diameter | ø70mm |

| Max. Loading Capacity | 5L |

| Speed Range | 200~11000 r/min |

| Work Head Stat-or Configuration | 5 mm2 20mm2 50mm2 |

| Volume Range | 40 L |

| Size of Main Frame | 280×360×750mm |

| Application for | liquid and suspended solid |

Related Products

-

MZH-AM POLYPROPYLENE ANTI-CORROSIVE MIXER

-

High Shear Dispersing Mixer for Powder and Liquid

Product Description:

Detail Description

Range of application Dispersion machine, also known as a blender. According to lift form that can be divided into the different hydraulic lift dispersion machine, pneumatic elevation dispersion machine and mechanical lifting dispersion machine. Widely used in the coatings, printing ink, paint, adhesives and other chemical products. This machine by the hydraulic system, main drive, mixing system, steering mechanism, electric cabinet of five parts, each part of the structure is compact, is reasonable. Scattered disc type: flat saw type, three righteousness paddle, dish and other forms.

The main features:

A, dispersion machine adopts stepless speed regulation: with electromagnetic speed control, frequency control of motor speed, such as used for water-based coating and explosion-proof variable frequency speed regulation (such as for oily coating), and other forms. Stepless speed regulation function can fully meet the technological process of different process requirement, can choose according to different stages of process different rotational speed. Powder without additives, the crystal package integrity materials shall not apply to the high demand.

Second, dispersion machine below the dispersion plate is laminar state, different flow velocity of pulp layer diffusion, dispersion effect. High-speed dispersion machine has the hydraulic elevator, 360 degrees of rotation, stepless speed regulation and other functions. Can configure 2-4 containers only at the same time, hydraulic lift travel 1000mm,360 degree rotation function can better meet multi-usage, can in a very short period of time from one shift to another cylinder for homework, dispersion machine greatly improves the work efficiency, but also reduces the manual labor intensity.

Quick View -

hydraulic lift emulsion mixing machine for paint

Description

High shear dispersing emulsifier effectively,quickly and evenly disperse a phase or phases to another consecutive phase,usually,these phases are dissolvable to each otherThe rotor revolves quickly and strong force is produced through high tangent speed and high frequency mechanical effect,therefore,the material in the narrow slotamong stator and rotor receives strong forces from mechanical and liquid shearing,centrifugal force,pressing,liquid fraction,clashing,tearing and rush water.

The dissolvable solid,liquid and gas material is then instantly dispersed and emulsified evenly and finely with better production procedures and appropriate addictives and finally products with stable high quality are made.

Quick View -

1.00 out of 5

MZH-F Liquid filling machine with heater and mixer

This machine is suitable to measurably fill the ointment materials with high viscosity and poor flow ability.It does the filling pneumatically, its hopper and the cylinder both are thermally preserved with electrically heated circulating water.The hopper is equipped with a frame mixing system.

Quick View -

MZH-V 3 layers electric heating soap mixer machine, blending machine for soap mixing

What we are about

We are a new high-tech company with a combination of design, manufacture, consultation and sale. Taking advantage of the professional standards and mechanical Engineering mellow technology in the field of chemical machinery, Now, This company is making great progress..

Follow us on:

Reviews

There are no reviews yet.