We shipp to all the world

You can get our machine either through air or sea.

Up to 10% off the bill

Contact us to know more about our special offers.After service

Our team will follow you until you master the machineManuals

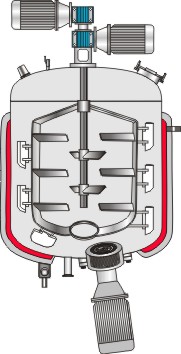

With the training we provide you manuals supported with videosMZH- 2000L liquid washing Heating homogenized mixer

Volume (L): 2000

Stirring power (kw): 5.5

Stirring speed (r/min): 0-53

Homogeneous power (kw): 11-15

Homogeneous rotational speed (r/min): 3000

Heating mode: steam or electric heating (optional)

Note: the data parameters of this device are inconsistent with technical improvement and customization.

Description

MZH- 2000L liquid washing Heating homogenized mixer

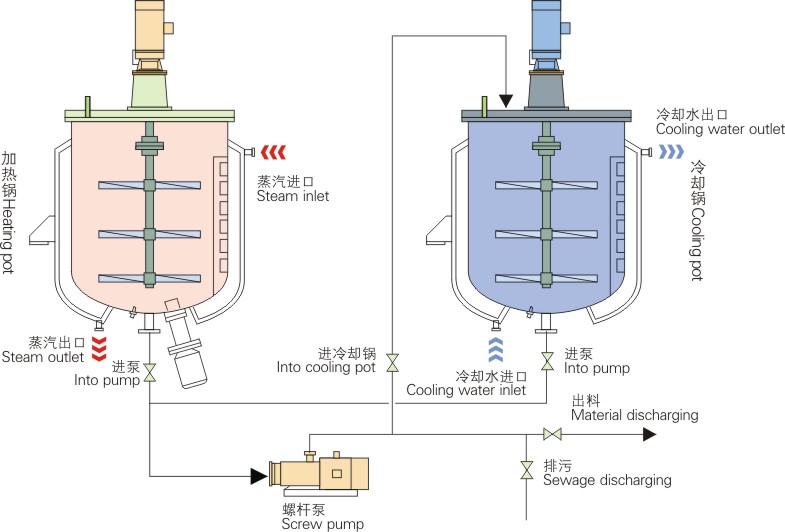

The reaction pot integrates the functions of agitation, homogenization, dispersion, heating, cooling, circulation, pump and so on, and is an ideal equipment for manufacturers to prepare liquid washing classes at present.

Use:

This unit is specially designed for small and medium-sized enterprises. The general production capacity can reach three times. The unit is divided into main pot, auxiliary pot, stainless steel delivery pump, support platform and control system. It only needs to be fed, dissolved, stirred and homogenized in the main pot, then the pump is fed into the auxiliary pot to cool and add flavors. When the material is out of material, it can also be put out and can be pumped out.

It is suitable for the working environment of electric heating. The main pot is used for homogenizing heating, and the auxiliary pot is directly used for cooling, emulsification, fast speed and high efficiency.

Performance and characteristics:

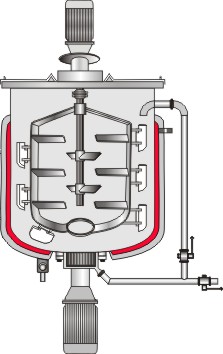

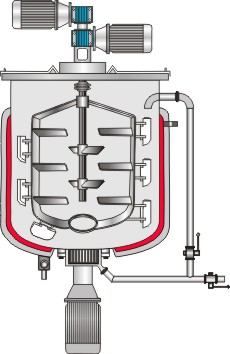

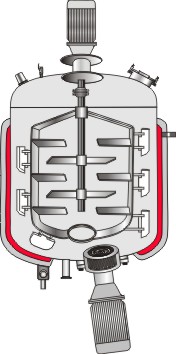

1, high speed disperser, strong mixing and dispersion, solid liquid raw materials can quickly dissolve AES, AESA, LSA and other hard dissolving materials in liquid washing production, save energy and shorten the production cycle.

Main stirring adopts continuously variable transmission device to reduce bubble formation at low temperature and high viscosity.

It is suitable for the production of any products of liquid washing.

It can be directly out of material and can also be supplied with screw pump.

Related Products

-

MZH-The newest and high quality Liquid vacuum emulsifying mixer machine for shampoo soap making line

MZH-The newest and high quality Liquid vacuum emulsifying mixer machine for shampoo soap making line

Quick Details

Voltage:380V

- Power(W):7.5KW

- Dimension(L*W*H):360*200*380

- Certification:CE,GMP

- material:stainless steel

- Supply Ability:60 Set/Sets per Month

Packaging Details :plywood carton packingQuick View -

External circulation vacuum Emulsifying mixer

USAGE & APPLICATION FIELD

The product is mainly applied in such industries as daily chemical care products, biopharmaceutical industry, food industry, paint and ink, nanometer materials, petrochemical industry, printing and dyeing auxiliaries, pulp & paper, pesticide, fertilizer, plastic & rubber, electrics and electronics, fine chemical industry, etc. The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

Download the description file: pdf format

Quick View -

MZH-M Liquid soap mixing machine

-

Fixed type homogenizer mixer

-

MZH-HYDRAULIC TYPE Lab Vacuum emulsifying mixer

What we are about

We are a new high-tech company with a combination of design, manufacture, consultation and sale. Taking advantage of the professional standards and mechanical Engineering mellow technology in the field of chemical machinery, Now, This company is making great progress..

Follow us on:

Reviews

There are no reviews yet.