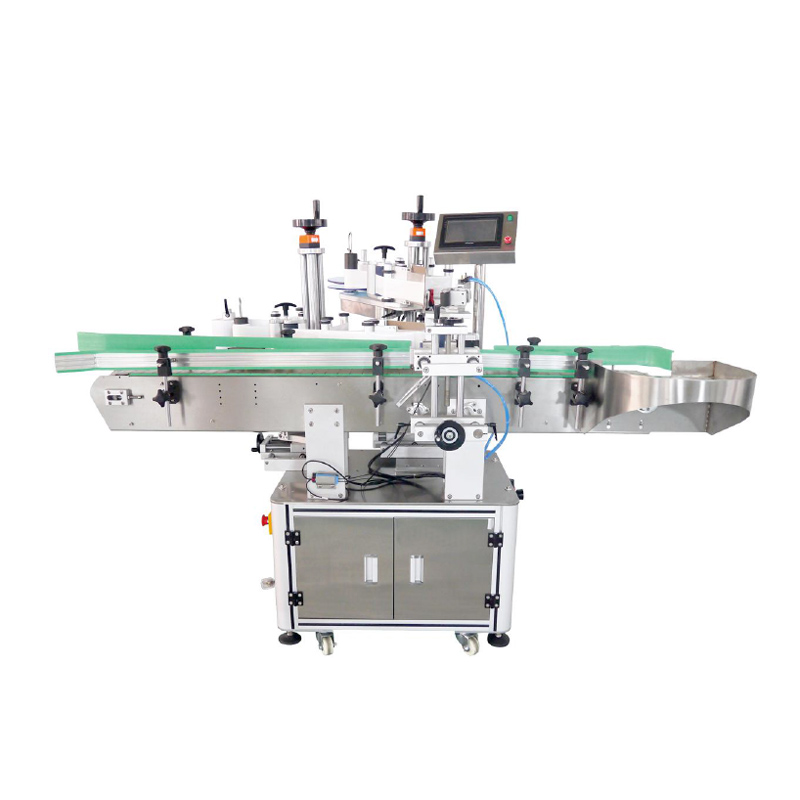

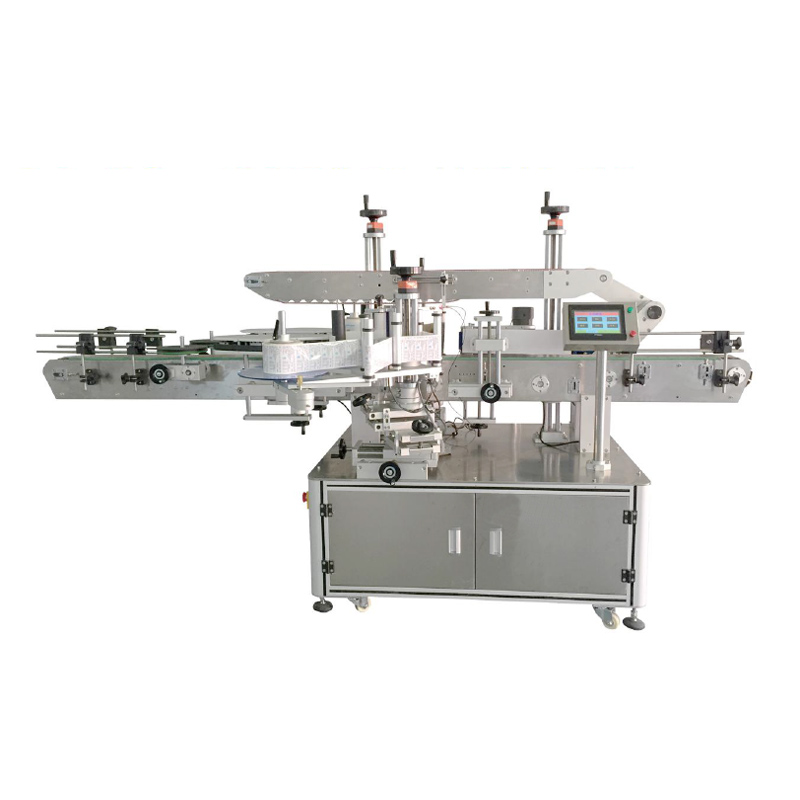

MZH-AL Round and Flat bottle labeling machine(Two kind bottles)

1.Optional automatic turntable unscramble bottle machine, can be connected directly to the front line, automatic bottle into the labeling machine, increase the efficiency.

2.Optional configuration ribbon code labeling machine, available online to print production date and batch number, reduce the bottle packaging process, improve production efficiency.

Description

MZH-AL Round and Flat bottle labeling machine(Two kind bottles)

- Main Purpose

Optional automatic turntable unscramble bottle machine, can be connected directly to the front line, automatic bottle into the labeling machine, increase the efficiency.

Optional configuration ribbon code labeling machine, available online to print production date and batch number, reduce the bottle packaging process, improve production efficiency.

- Working Principle

Core working principle: separate products, bottle mechanism with sensors to detect the product after, back to the signal to the labeling control system, in the appropriate place

Control system to control the motor sent out labels and attached with a stay in product labeling position, product flows through the device, the belt driven in product, label roll cladding, a label attached.

Operation: put a product (line) – > product delivery (device automatically) – > product separation – > product testing – > label – > collection were post logo products.

III. Suitable Scope

Applicable tag: the non-drying label, dry film, electronic supervision code, bar code, etc.

Applicable products: request attached with a tag on the circumference of a circle or membrane products.

Application industry: widely used in food, medicine, cosmetics, daily chemical, electronics, metal, plastic and other industries.

Application example: PET Flat bottle, round bottle label, plastic bottle labeling, food cans, etc.

- Feature

- Applicability is wide and can meet the whole week of round bottle labeling or half circle label, the bottle label switching between simple, easy to adjust;

B. label contact ratio is high, the band around a correction institutions, take not to deviate, labeling and x/y/z three directions and gradient, a total of eight degrees of freedom is adjustable, no dead Angle adjustment, label high contact ratio;

C. Labeling quality, adopts of taliban sex standard belt, labeling smooth, no wrinkles, improve packaging quality.

D. Application flexibility, bottle stand of labeling, have automatic bottle dividing function, it can produce single also can meet production line;

E. Intelligent control, automatic photoelectric tracking, have any label, there is no standard automatic correction and label automatic detection function, prevent leakage and labels to waste;

F. High stability, Siemens PLC + + Germany’s Siemens touch screen is easy to measure label advanced electronic control system of electric eye, 7 * 24 hours support equipment operation;

G. Easy, labeling speed, transmission speed, the bottle can realize step less speed regulation, according to the need to adjust;

H. Hurable, using three rod adjustment mechanism, make full use of the stability of the triangle, the whole machine solid and durable.Stainless steel and advanced aluminum alloy,

In line with the GMP production requirements;

I. optional features:

(1) hot code/printing function;

(2) the function of automatic feeding (consider) combined with products;

(3) automatic discharging function (consider) combined with products;

(4) increase the labeling device;

(5) circular circumferential orientation labeling functions;

(6) Other functions () according to the requirements of client.

- Round bottle Technical Parameter

The following technical parameters of model machine, other special requirement and function, can be customized

| Model | MZH-L |

| Apply label length (mm) | 20 mm to 314 mm |

| Mixer is the label width (bottom paper width/mm) | 15 mm to 150 mm |

| Mixer applicable products (for round bottle) in diameter and height | diameter, from 25 mm to 100 mm

height: 25 mm to 230 mm |

| Pieces for the roll diameter (mm) | phi 280 mm |

| Apply the roll diameter (mm) | phi 76 mm |

| Labeling accuracy (mm) | + / – 1 mm |

| Out the speed (m/min) | step: 5 ~ 19 m/min servo: 5 ~ 25 m/min |

| Labeling speed (PCS/min) | step: 30 ~ 80 PCS/min (related to the bottle and label size) servo: 40 ~ 120 PCS/min |

| Conveyor speed (m/min) | 5 ~ 25 m/min |

| Weight (kg) | about 185 kg |

| Frequency (HZ) | 50HZ |

| Voltage (V) | 220 – V |

| Power (W) | (step) traction 980 W, 530 W (traction servo) |

| Mixer device dimension (mm) (length x width x height) | 2550 mm *1300 mm * 1650 mm. |

- Flat bottle Technical Parameter

| Model | MZH-L |

| The label maximum width (ie, elevation) | 200mm (the visual customer specific requirements be made separately.) |

| Label label maximum diameter | 300 mm |

| Labeling accuracy (mm) | + / – 1 mm |

| Out the speed (m/min) | 40 m / min |

| Core diameter | 76.2 mm |

| Conveyor speed (m/min) | 5 ~ 25 m/min |

| Weight (kg) | about 550kg |

| Frequency (HZ) | 50HZ |

| Voltage (V) | 220 – V |

| Power (W) | (step) traction 980 W, 530 W (traction servo) |

| Mixer device dimension (mm) (length x width x height) | 3000 mm *1300 mm * 1650 mm. |

Reviews

There are no reviews yet.