Automatic 12 Holes stainless steel lipstick filling machine cosmetic machinery

Product Application:

1)The machine is designed pointed to liquid cosmetics,i.e.lipstick,pencil lipstick,brow pencil,lip oil,lip balm…etc

2)Individual object barrel stirring and temperature control design,meet the requirements of varieties of raw materials.

3)It adopts advanced automization technics (human machine interface,PLC program control), parameters including time and temperature control from the whole machine needing to set all is completed by human machine interface.

Simplify operating system program and make the machine function stabler.

4)The machine adopts aluminum extrusion construction,easy to clean on the aluminum station.

5)System operation program is simple,it does not take time to educate and train.

6)Every unit (including object barrel,pump,object tube,nozzle)all adopts intelligent temperature control individually,temperature control precision is ±0.3℃,make the equipment easier operate.

7)Auto-counter.

Description

Automatic 12 Holes stainless steel lipstick filling machine cosmetic machinery

Main Features:

1, This product ejection device designed for lipstick. After artificial socket red tube, put the machine above, can automatically dial the mold, mold release.

2, Using PLC interface easy to operate. Modulus can be installed directly on the screen, dial the mould, the time of mold release.

3, Concise convenient maintenance of the machine and control design.

4, Reduce production process, improve work efficiency.

5, Light volume does not occupy a space.

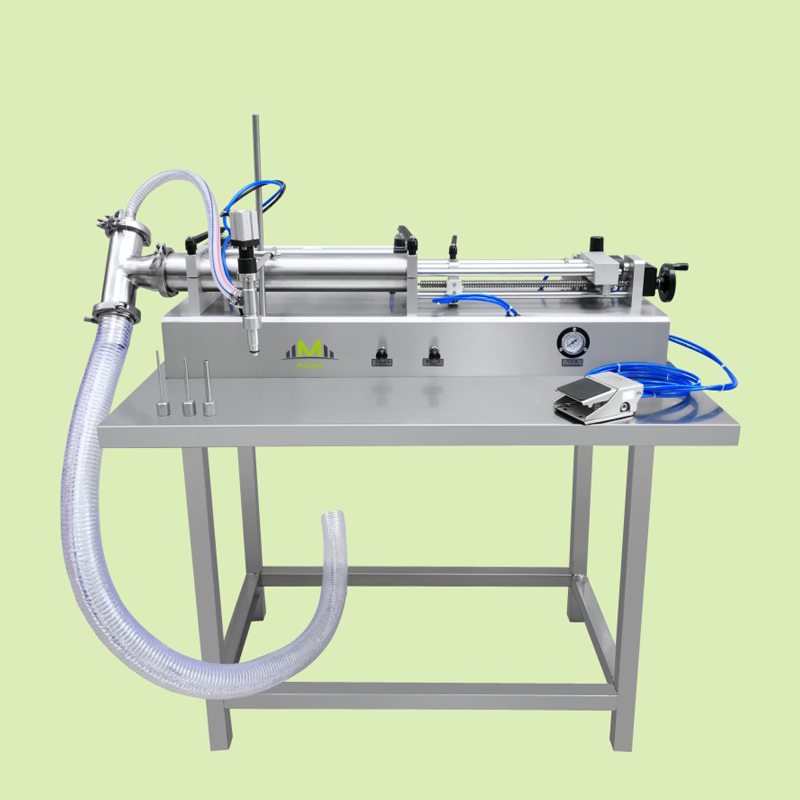

6, Pneumatic drive, easy to maintenance and cleaning.

7, Side design, avoid friction damage and jams at the bottom of the porosity in the mold.

Machine parameters:

|

Filling range |

1-20ml |

|

Filing speed |

50-80per minute |

|

Filling Precision |

±1% |

|

Internal Barrel Size |

Φ300*300mm |

|

Station Height |

720mm |

|

Heated Power |

4.2KW |

|

Object Barrel Volume |

20L, double lips object barrel heat isolated oil |

|

Filling Range |

1~14ml/pcs |

|

Air Shrink |

6KG/cm² |

|

Total Power |

4.5KW |

|

Dimensions |

900mm*900mm*1950mm |

|

Power Supply |

AC380V/3ψ/50Hz |

Reviews

There are no reviews yet.