We shipp to all the world

You can get our machine either through air or sea.

Up to 10% off the bill

Contact us to know more about our special offers.After service

Our team will follow you until you master the machineManuals

With the training we provide you manuals supported with videossemi automatic bottle capping machine for multiple cap sizes and materials

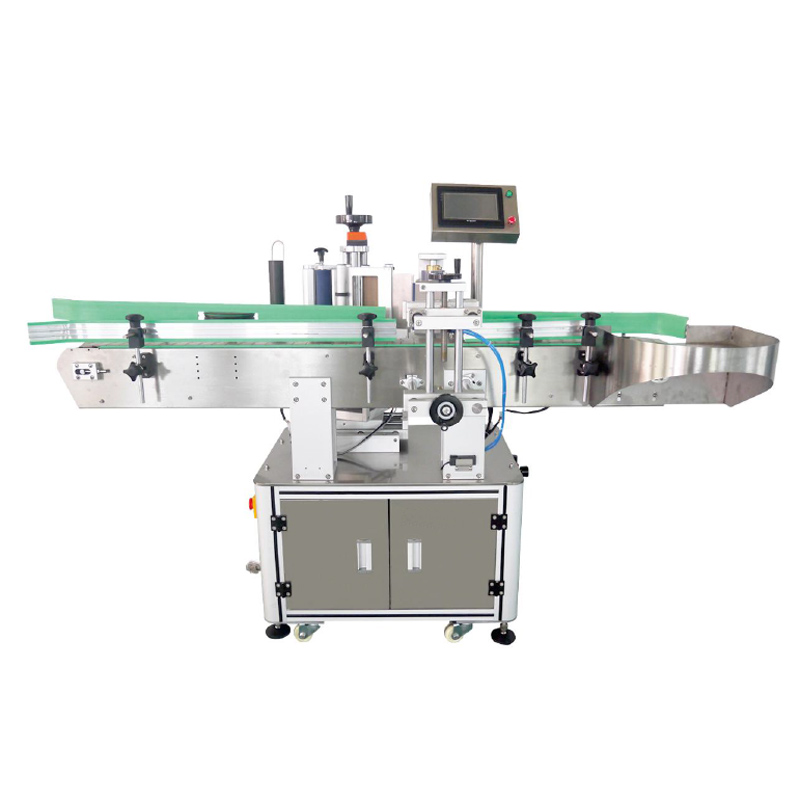

DESCRIPTION

1.The machine is suitable for food, beverage, chemical industry, pesticide, cosmetics

for all kinds of bottle type of clamp capping.

2.It can be suitable for many different dimension and material of bottle clamp cap by

simple adjusting . Besides, ere is no need to replace any assembly.

Description

semi automatic bottle capping machine for multiple cap sizes and materials

TECHNICAL SPECIFICATIONS

|

Capping diameter |

φ20mm-φ55mm | ||

|

Max bottle height |

300mm | ||

|

Voltage |

220V50Hz |

||

| Timer brand |

Omron |

||

| Weight |

28kg |

||

|

Overall Dimension |

5300mm×450mm×600mm | ||

|

Voltage |

220V50Hz |

||

| Power |

90W |

||

|

Dimension |

480*400*580mm | ||

|

Net weight |

30kg | ||

| Use air |

0.4-0.6Mpa |

||

| Lock cover range |

16-50mm |

||

|

Lock bottles of range |

H:50-400mm W:20-100mm | ||

| Pot speed |

30-45pcs/min |

||

|

Capping torsion |

4-8KG/CM |

||

Related Products

-

Screw Filling Machine for flour and baby powder

The machine is semi automatic series filling packaging machine, Modular transparent hopper. Horizontalhopper opening, platform, human-computer interface, PLC control weighing module. Servo motor drive screw, 304 stainless steel, to adapt to the artificial bagged, bottles, cans, boxes of filling.

Quick View -

Automatic 12 Holes stainless steel lipstick filling machine cosmetic machinery

Product Application:

1)The machine is designed pointed to liquid cosmetics,i.e.lipstick,pencil lipstick,brow pencil,lip oil,lip balm…etc

2)Individual object barrel stirring and temperature control design,meet the requirements of varieties of raw materials.

3)It adopts advanced automization technics (human machine interface,PLC program control), parameters including time and temperature control from the whole machine needing to set all is completed by human machine interface.

Simplify operating system program and make the machine function stabler.4)The machine adopts aluminum extrusion construction,easy to clean on the aluminum station.

5)System operation program is simple,it does not take time to educate and train.

6)Every unit (including object barrel,pump,object tube,nozzle)all adopts intelligent temperature control individually,temperature control precision is ±0.3℃,make the equipment easier operate.

7)Auto-counter.

Quick View -

MZH-PM hot sale high quality perfume glass bottles filling machine with four heads

Product Description:

MZH-FP perfume spray filling machine is the latest Liquid Water filling machine .under each filling nozzle there have a sensor.When the bottle ready put at filling nozzle then filling.More stable and convenience.

1.Performance Introduction:

1.) MZH-FP perfume spray filling machine adopt fully pneumatic control so it is very suitable for the filling of high foam materials and different capacity of containers.2.) The design concept is: through increase pressure on the filling head, vacuum generator achieve a partial sealing environment in the reflow liquid bottle and filling container. Thus generate a partial vacuum(negative pressure) through vacuum suction to achieve filling process.

2.Instruction

This machine is specially used for the sealing of all types of liquid water bottles which after sealing they can keep good sealing performance even under the inclement environment. The work system and control system of this machine adopt pneumatic.Quick View -

MZH-L Automatic positioning circular bottle labeling machine

-

Factory price stainless steel reverse osmosis water treatment

Product Description

I. Technical process

Tap water→booster pump→sand filter→carbon filter→5µS security filter→

high pressure pump→stainless steel pump→500L/H RO system→ well water

II. Configuration

A. Two stainless steel 304 barrels attached American auto device

B. Equipped with booster pumps, stopped automatically when there is no water

besides it will add pressure when low pressure.

C. High pressure pump. Imported solenoid valve. Imported DOW membrane,

whose unit desalination rate is 99%. The whole set is 97%-98%.

D. Pressure protection device imported from Korea which used to protect the

high pressure pump.

E. Membrane automatic rinse as the machine is operated, digital time control

F. Fully automatically feeding water G. Raw water conductivity≤400us/cm, well water conductivity≤10us/cm

Quick View

What we are about

We are a new high-tech company with a combination of design, manufacture, consultation and sale. Taking advantage of the professional standards and mechanical Engineering mellow technology in the field of chemical machinery, Now, This company is making great progress..

Follow us on:

Reviews

There are no reviews yet.