Portable shearing homogenizing mixer

- large capacity, suitable for industrial continuous production on-line;

The 2. particle size distribution is narrow and the evenness is high.

- provinces, high efficiency, energy saving;

- the noise is low and the operation is smooth.

- eliminate the quality difference between batch production.

Description

-

MZH-DM High shear dispersing emulsifier mixer

Description

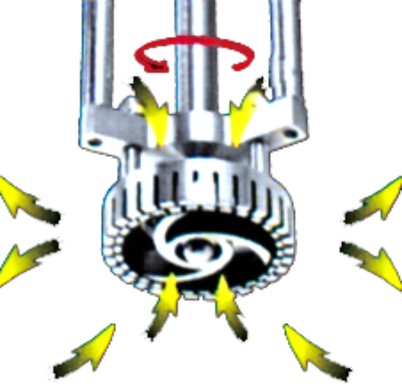

High shear dispersing emulsifier effectively,quickly and evenly disperse a phase or phases to another consecutive phase,usually,these phases are dissolvable to each otherThe rotor revolves quickly and strong force is produced through high tangent speed and high frequency mechanical effect,therefore,the material in the narrow slotamong stator and rotor receives strong forces from mechanical and liquid shearing,centrifugal force,pressing,liquid fraction,clashing,tearing and rush water.The dissolvable solid,liquid and gas material is then instantly dispersed and emulsified evenly and finely with better production procedures and appropriate addictives and finally products with stable high quality are made.

Function

This machine adopt toproduce low viscosity product,which can homogenizing,emulsifying,shearing, rubbing,then make the material reach to a very steady condition.The material can reach1-2um.

Technical data

| Model | Power(KW) | Speed(rpm) | Capacity(L) |

| MZH-90 | 1.5 |

2800-2900

|

5~50 |

| MZH-100 | 2.2 | 50~100 | |

| MZH-120 | 4 | 100~300 | |

| MZH-140 | 7.5 | 200~800 | |

| MZH-160 | 11 | 300~1000 | |

| MZH-180 | 18.5 | 500~1500 |

-

High shear homogenization emulsification equipment

High shear dispersion emulsifier is an efficient, rapid and uniform distribution of one or more phases in another continuous phase, and in ordinary cases each phase is insoluble. Due to the strong kinetic energy caused by high shear speed and high frequency mechanical effect produced by high speed rotation of the rotor, the material is subjected to a strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tearing and turbulence in the narrow gap between fixed and rotor, so that the insoluble solid phase, liquid phase and gas phase are in phase. Under the joint action of mature technology and proper amount of additives, the emulsification is dispersed uniformly and finely in a moment, and the stable high quality products are finally obtained through high frequency circle cycle.

Characteristics of pipeline type high shear dispersion emulsifier:

- large capacity, suitable for industrial continuous production on-line;

The 2. particle size distribution is narrow and the evenness is high.

- provinces, high efficiency, energy saving;

- the noise is low and the operation is smooth.

- eliminate the quality difference between batch production.

- the suction port of homogenizer can directly suck some raw materials into the stator after shearing and then flow out of the pump body.

- without dead angle, material 100% by dispersing shear;

- has the function of short distance and low lift.

- easy to use, convenient maintenance;

- can realize automatic control.

-

MZH-DM High shear Dispersing homogenizing mixer

Stainless steel High shear Dispersing homogenizing mixer, High shear dispersion emulsifier is an efficient, rapid and uniform distribution of one or more phases in another continuous phase, and in ordinary cases each phase is insoluble. Due to the strong kinetic energy caused by high shear speed and high frequency mechanical effect produced by high speed rotation of the rotor, the material is subjected to a strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tearing and turbulence in the narrow gap between fixed and rotor, so that the insoluble solid phase, liquid phase and gas phase are in phase. Under the joint action of mature technology and proper amount of additives, the emulsification is dispersed uniformly and finely in a moment, and the stable high quality products are finally obtained through high frequency circle cycle.

Characteristics of pipeline type high shear dispersion emulsifier:

- large capacity, suitable for industrial continuous production on-line;

The 2. particle size distribution is narrow and the evenness is high.

- provinces, high efficiency, energy saving;

- the noise is low and the operation is smooth.

- eliminate the quality difference between batch production.

- the suction port of homogenizer can directly suck some raw materials into the stator after shearing and then flow out of the pump body.

- without dead angle, material 100% by dispersing shear;

- has the function of short distance and low lift.

- easy to use, convenient maintenance;

- can realize automatic control.

Reviews

There are no reviews yet.