We shipp to all the world

You can get our machine either through air or sea.

Up to 10% off the bill

Contact us to know more about our special offers.After service

Our team will follow you until you master the machineManuals

With the training we provide you manuals supported with videosMZH-V vacuum homogenizing emulsifying mixer( shampoo, liquid soap, detergent, pesticide…. mixing machine) (Copy)

- Condition:New

- Mixer Type:Homogenizer

- Additional Capabilities:Homogenizer mixer

- Max. Loading Capacity:5-5000L, customized

- Voltage:220V/380V 50HZ, 3KW

- Power(W):15-88KW

- Dimension(L*W*H):2920*2120*2200mm

- Certification:SGS/CE/ISO9001

- Effective capacity:100L

- Emulsify:0-3800 R/min

- contact material:SUS316L

- blender:0-63r/m speed adjustable

- additonal capabilities:mixing&emulsifying

- outlet:tilting system

Description

MZH-V vacuum homogenizing emulsifying mixer( shampoo, liquid soap, detergent, pesticide…. mixing machine)

| Model | Effective capacity | Emulsify | Agitator | Dimension(MM) | Total power(KW) | ||||||

| KW | R/min | KW | R/min | Length | Width | Height | Maxh | Electric heating | Steam heating | ||

| MZH-V-20 | 20 | 0.75 | 0-3000 | 0.37 | 0-40 | 1800 | 1600 | 1850 | 2700 | 9 | 3 |

| MZH-50 | 50 | 2.2 | 0-3000 | 0.37 | 0-40 | 2700 | 2000 | 2015 | 2700 | 25 | 5 |

| MZH-100 | 100 | 3 | 0-3000 | 1.5 | 0-40 | 2920 | 2120 | 2200 | 3000 | 27 | 9 |

| MZH-150 | 150 | 3 | 0-3000 | 1.5 | 0-40 | 3110 | 2120 | 2200 | 3100 | 27 | 9 |

| MZH-200 | 200 | 4 | 0-3000 | 1.5 | 0-40 | 3150 | 2200 | 2200 | 3100 | 40 | 12 |

| MZH-350 | 350 | 4 | 0-3000 | 2.2 | 0-40 | 3650 | 2650 | 2550 | 3600 | 50 | 16 |

| MZH-500 | 500 | 5.5 | 0-3000 | 2.2 | 0-40 | 3970 | 2800 | 2700 | 3950 | 50 | 16 |

| MZH-1000 | 1000 | 11 | 0-3000 | 4 | 0-40 | 3900 | 3400 | 3150 | 4550 | 100 | 30 |

| MZH-2000 | 2000 | 15 | 0-3000 | 7.5 | 0-40 | 4850 | 4300 | 3600 | no rise and fall | 120 | 50 |

Features of shampoo emulsifier:

The vacuum emulsifier is professionally designed according to the ointment manufacturing process of

cosmetics and ointments etc. products through

introducing advanced technology from abroad. The machine unit is composed of pre-treating boiler,

vacuum emulsifying and blending boiler, vacuum pump,

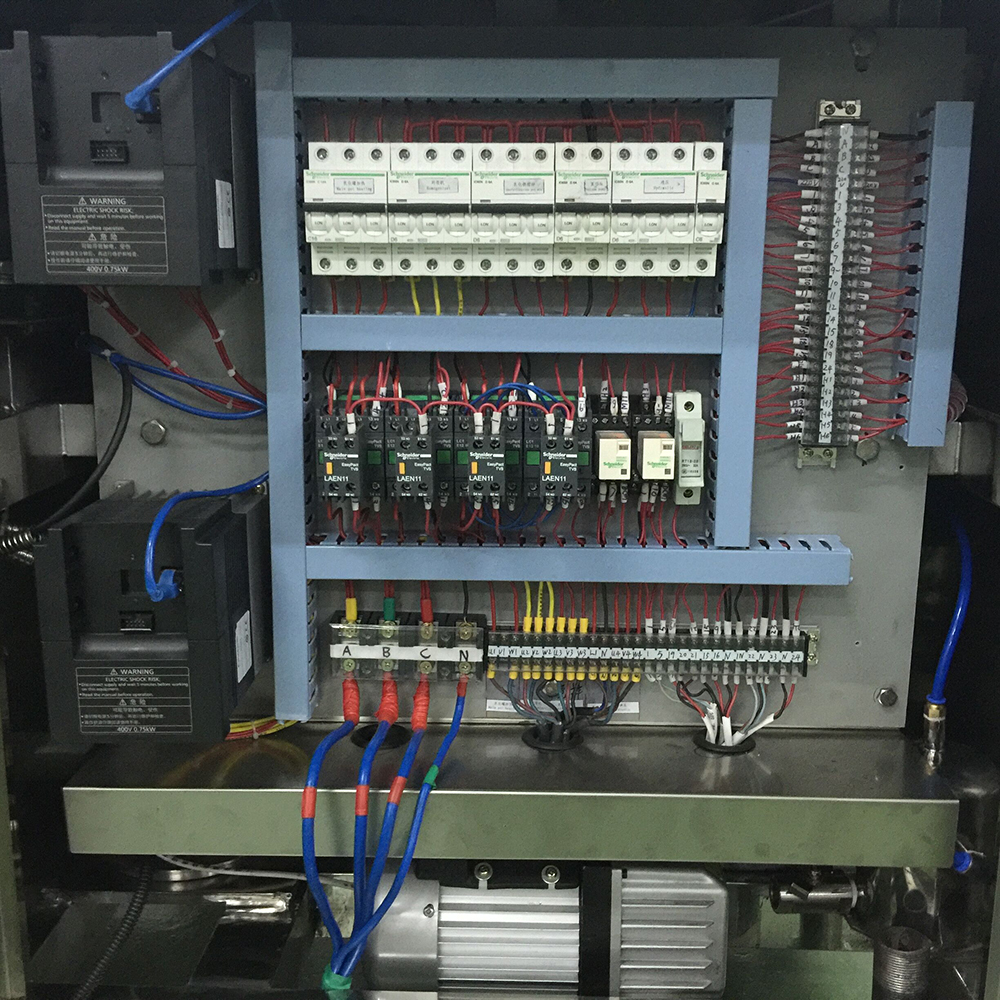

hydraulic system, dumping system, electric control system and work platform etc. The machine unit is

featured by simple operation, stable performance, good homogenizing performance, high production

efficiency, convenient cleaning, reasonable structure, small land area and high automatic degree etc

Usage of shampoo emulsifier:

It is suitable for production of ointment and cream products in cosmetic and pharmaceutical plants.

The emulsifying effect is more prominent for materials

of high base viscosity and high solid content.

Advantage:

1. Homogenizer’s design mainly stem from Japanese technology.

2. Completely Meet GMP

3. Material contact part all use SUS316L

4. Using Japan NSK bearings

5. Siemens Inverter, power-saving, machine-protect, keeping the machine working stably

6. Burgmamn mechanical seal, seal good, long working life, keep the homogenizer work 24 hours continually.

7. Slow stirring axle adopts 2 sets of mechanical seal and 2 sets frame oil seal, make the seal saver.

8. Stirring scrap and middle stirring rotating the opposite direction make the mixing more equally

9. Safety protecting functions, make the produce saver

10. Install a fall buffer unit on the hydro-cylinder in the hydraulic system; keep the cover up and down

stable.

Machinery main parts:

1. Q: Ae you factory or trading company?

A: We are the professional manufacture of cosmetic machinery in China more than 10years

2. Q: Where is your location?

A: Company and Showroom located in Guangzhou china, Factory located in Jiangsu and Shanghai Province.

3. Q: Are your engineer be able to serve in oversea?

A: Yes, we have a lot of experience install the machine in oversea.

4. Q: What is your material of your product?

A: adopt with full stainless steel 304-2b and 316L

5. Q: How does your factory do regarding quality control?

A: Two years spare parts,and full-life service of our machinery.

Our Company to customer satisfaction for the development of three goals: product quality, product technology and after-sales service!

Related Products

-

MZH-M Liquid mixing machine

-

Screw Filling Machine for flour and baby powder

The machine is semi automatic series filling packaging machine, Modular transparent hopper. Horizontalhopper opening, platform, human-computer interface, PLC control weighing module. Servo motor drive screw, 304 stainless steel, to adapt to the artificial bagged, bottles, cans, boxes of filling.

Quick View -

MZH-L Semi automatic plane adsorption labeling machine

Scope of application

Applicable labels: stickers, adhesive film, electronic monitoring code, bar code and so on.

Applicable Products: Products that need to be labeled on flat, curved, circumferential, concave, convex or other surfaces

Application Industry: widely used in cosmetics, food, toys, daily chemical, electronics, medicine and other industries.

Examples are: shampoo flat bottle labeling, packing box labeling, bottle cap, plastic shell labeling, etc.

Quick View -

MZH-M Liquid soap mixing machine

-

Lab Vacuum emulsifying mixer

Technical features: the cover of main boiler tank can be lifted and lowered automatically, and it is up-homogenizer homogenizer to enhance the homogenizing effect of materials to the greatest extent.

Working capacity: 10L, 20L, 30L

Homogenizing speed: 50-3600RPM (frequency conversion speed adjustment)

Quick View

What we are about

We are a new high-tech company with a combination of design, manufacture, consultation and sale. Taking advantage of the professional standards and mechanical Engineering mellow technology in the field of chemical machinery, Now, This company is making great progress..

Follow us on:

Reviews

There are no reviews yet.