MZH-V 3 layers electric heating soap mixer machine, blending machine for soap mixing

- Max. Loading Capacity:1000L

- Voltage:380V 50-60Hz

- Power(W):49KW

- Dimension(L*W*H):1.25*0.75*1.35M

- Certification:CE/ISO9001/SGS

- Blender Material:SUS316L

- Homogenizer speed:0-3600RPM

- Homogenizer:ABB Motor Brand

- Mixing speed:0-63RPM

Description

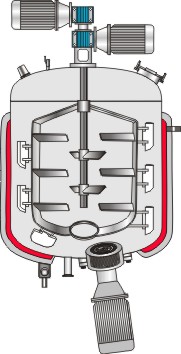

MZH-V 3 layers electric heating soap mixer machine, blending machine for soap mixing

Machinery Introduction:

1. MZH-M1000L MZH-V 3 layers electric heating soap mixer machine, blending machine for soap mixing adopts single-direction or doubledirection scraping blending and frequency. conversion speed adjustment,

so as to satisfy product of different technological requirements.

2. According to technological requirements, the materials can be heated or cooled. The heating method can be chosen steam or electric heating according to customer.

3. Various forms of blending vanes are suitable for production of different types of products.

4. Made of imported SUS304 or SUS306L stainless steel. The tank body and pipe are carried out mirror polishing.

5. Vacuum pump can be equipped to carry out vacuum defoaming (optional).

6. Bottom installation type dispersing head and emulsifying head are optional to speedup dissolution and emulsification of materials.

7. The stainless steel electric control cabinet can completely supervise the operation of equipment, and display data, such temperature and blending rotation speed etc.

TECHNICAL SPECIFICATIONS

| Name | MZH-M1000L MZH-V 3 layers electric heating soap mixer machine, blending machine for soap mixing |

| Volume of Mixer | 1000L |

| Inner jacket Material | SUS316L(6mm) |

| Middle jacket Meterial | SUS304-2B(6mm) |

| Out jacket Material | SUS304-2B(3mm) |

| Paddle Material | SUS316L |

| Homogenizer Speed(SIEMENS) | 0-2880 r/min |

| Homogenizer Power | 7.5kw |

| Speed of Scraping Plate Blender(frequency converter) | 0-63 r/min |

| Blender Power(SIEMENS) | 4kw |

| Temperature of Mixer | ≤100 ℃ |

| Voltage | 50-60Hz

380V±10%-15% |

FAQ

1. Q: Are you factory or trading company?

A: We are the professional manufacture of cosmetic machinery in China more than 10years

2. Q: Where is your location?

A: Company and Showroom located in Guangzhou china, Factory located in Jiangsu and Shanghai Province.

3. Q: Are your engineer be able to serve in oversea?

A: Yes, we have a lot of experience install the machine in oversea.

4. Q: What is your material of your product?

A: adopt with full stainless steel 304-2b and 316L

5. Q: How does your factory do regarding quality control?

A: Two years spare parts,and full-life service of our machinery.

Our Company to customer satisfaction for the development of three goals: product quality, product technology and after-sales service!

Reviews

There are no reviews yet.