We shipp to all the world

You can get our machine either through air or sea.

Up to 10% off the bill

Contact us to know more about our special offers.After service

Our team will follow you until you master the machineManuals

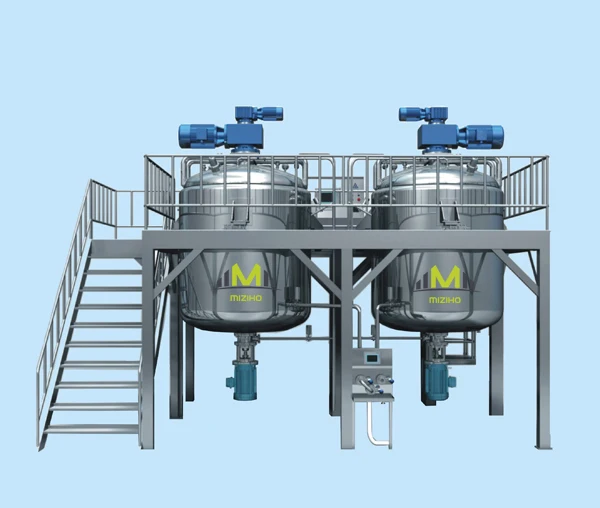

With the training we provide you manuals supported with videosMZH-The newest and high quality Liquid vacuum emulsifying mixer machine for shampoo soap making line

Quick Details

Voltage:380V

- Power(W):7.5KW

- Dimension(L*W*H):360*200*380

- Certification:CE,GMP

- material:stainless steel

- Supply Ability:60 Set/Sets per Month

Description

MZH-The newest and high quality Liquid vacuum emulsifying mixer machine for shampoo soap making line

The newest and high quality PME-Liquid soap machine From MZH

Specifications

liquid cosmetic mixing tank

1. 316L stainless steel

2. button control

3. mixing and homogenizing

PME liquid mixer machine automatic

1. Capacity: 5~5000L

2. Contact parts: three jackets, inside layer adopt SS 316L, the

3. middle and outer layers adopt SS304-2B,

4. Homogenizer speed: 0~3000rpm, two types of speed control:

5. Scraper speed: 0~63rpm

6. Centre shaft speed: 0~63rpm

7. Lift: hydraulic lift system

8. Heat: steam/electrically

9. Operation: automatic (PLC)/manually

Grade: GMP (optional)

Motor adopt siemens or US A ABB brand

![]()

![]()

Related Products

-

Lift Homogenizer mixer for tooth paste

this company produces the vacuum emulsifying type varieties diverse, including homogeneous system points on homogeneous under homogeneous, both inside and outside circulation homogeneous, mixing system and two-way one-way stirring, ribbon stirring;The lifting system is divided into single cylinder and double cylinder lifting, and can be customized according to customer request a variety of meets the demand of high quality products.

Quick View -

MZH-200L liquid washing homogenizing mixer

Volume (L): 200

Stirring power (kw): 0.75

Stirring speed (r/min): 0-65

Homogeneous power (kw): 2.2-4

Homogeneous rotational speed (r/min): 3000

Heating mode: steam or electric heating (optional)

Note: the data parameters of this device are inconsistent with technical improvement and customization.

Quick View -

High Shear Dispersing Mixer for Powder and Liquid

Product Description:

Detail Description

Range of application Dispersion machine, also known as a blender. According to lift form that can be divided into the different hydraulic lift dispersion machine, pneumatic elevation dispersion machine and mechanical lifting dispersion machine. Widely used in the coatings, printing ink, paint, adhesives and other chemical products. This machine by the hydraulic system, main drive, mixing system, steering mechanism, electric cabinet of five parts, each part of the structure is compact, is reasonable. Scattered disc type: flat saw type, three righteousness paddle, dish and other forms.

The main features:

A, dispersion machine adopts stepless speed regulation: with electromagnetic speed control, frequency control of motor speed, such as used for water-based coating and explosion-proof variable frequency speed regulation (such as for oily coating), and other forms. Stepless speed regulation function can fully meet the technological process of different process requirement, can choose according to different stages of process different rotational speed. Powder without additives, the crystal package integrity materials shall not apply to the high demand.

Second, dispersion machine below the dispersion plate is laminar state, different flow velocity of pulp layer diffusion, dispersion effect. High-speed dispersion machine has the hydraulic elevator, 360 degrees of rotation, stepless speed regulation and other functions. Can configure 2-4 containers only at the same time, hydraulic lift travel 1000mm,360 degree rotation function can better meet multi-usage, can in a very short period of time from one shift to another cylinder for homework, dispersion machine greatly improves the work efficiency, but also reduces the manual labor intensity.

Quick View -

MZH-V 3 layers electric heating soap mixer machine, blending machine for soap mixing

-

hydraulic lift emulsion mixing machine for paint

Description

High shear dispersing emulsifier effectively,quickly and evenly disperse a phase or phases to another consecutive phase,usually,these phases are dissolvable to each otherThe rotor revolves quickly and strong force is produced through high tangent speed and high frequency mechanical effect,therefore,the material in the narrow slotamong stator and rotor receives strong forces from mechanical and liquid shearing,centrifugal force,pressing,liquid fraction,clashing,tearing and rush water.

The dissolvable solid,liquid and gas material is then instantly dispersed and emulsified evenly and finely with better production procedures and appropriate addictives and finally products with stable high quality are made.

Quick View

What we are about

We are a new high-tech company with a combination of design, manufacture, consultation and sale. Taking advantage of the professional standards and mechanical Engineering mellow technology in the field of chemical machinery, Now, This company is making great progress..

Follow us on:

Reviews

There are no reviews yet.