We shipp to all the world

You can get our machine either through air or sea.

Up to 10% off the bill

Contact us to know more about our special offers.After service

Our team will follow you until you master the machineManuals

With the training we provide you manuals supported with videosMZH-S Best price continuous plastic bottle aluminum foil induction sealing machine

Feature:

1.high sealing speed, suitable for batch production.

2.easy to operate, good performance, with auto on/off function.

3.high efficiency (0-160bot/min), good quality

4.sealing dia (15mm – 120mm)

Alert System:

This machine with auto-alert system which alarm when there is no aluminum foil and machine is working. When working, Put metal sensor point at 2 – 3 mm above the top of bottle cap, then adjust photosensor position so that can sense bottle cap, and machine working.

Description

MZH-S Best price continuous plastic bottle aluminum foil induction sealing machine

Technical Parameter:

|

Power supply |

AC220V 50/60Hz |

|

Max power |

2500W |

|

Sealing dia (Optional) |

15-50mm 35-100mm 50-120mm |

|

Conveyor Belt speed |

8.5M/min |

|

Sealing machine |

polyethylene bottle with bottle mouth dia 35mm, bottle bottom dia 40mm |

|

Cooling way |

Cold wind |

|

Sealing height |

20-350mm |

|

Working way |

Continuous working |

|

Material |

Stainless steel |

|

Machine dimension (L*W*H) |

1300×1250×350(mm) |

|

Packing dimension(L*W*H) |

1450×1400×420(mm) |

|

Net Weight |

42kg |

Related Products

-

Ultrasonic plastic bags popsicle packing liquid filling sealing machine

Machine Parameters:

Power supply

220v50Hz pressure 0.6Mpa

The sealing efficiency 20-25 PCS/min

Filling accuracy ±1%

The sealing height 30~220mm(customizable)

Frequency

20KHz

Sealing diameters

15~50mm(customizable)

Power

2KW

Filling range

5-60ML,10-120ML,25-250ML

Dimension

L1300*W900*H1550mm

Weight 350kgs

Machine configuration details :(the following configuration is a standard model, optional according to customer requirements)

Ultrasonic system

HANGSON Digital automatic frequency tracking Benchmarking electric eye

Japan Panasonic PLC

Coolmay

Relay Touch Screen Coolmay

Quick View -

MZH-V vacuum homogenizing emulsifying mixer( shampoo, liquid soap, detergent, pesticide…. mixing machine)

Quick Details

Quick Details- Max. Loading Capacity:5-5000L, customized

- Voltage:220V/380V 50HZ, 3KW

- Power(W):15-88KW

- Dimension(L*W*H):2920*2120*2200mm

- Certification:SGS/CE/ISO9001

- Effective capacity:100L

- Emulsify:0-3800 R/min

- contact material:SUS316L

- blender:0-63r/m speed adjustable

- additonal capabilities:mixing&emulsifying

- outlet:tilting system

Quick View -

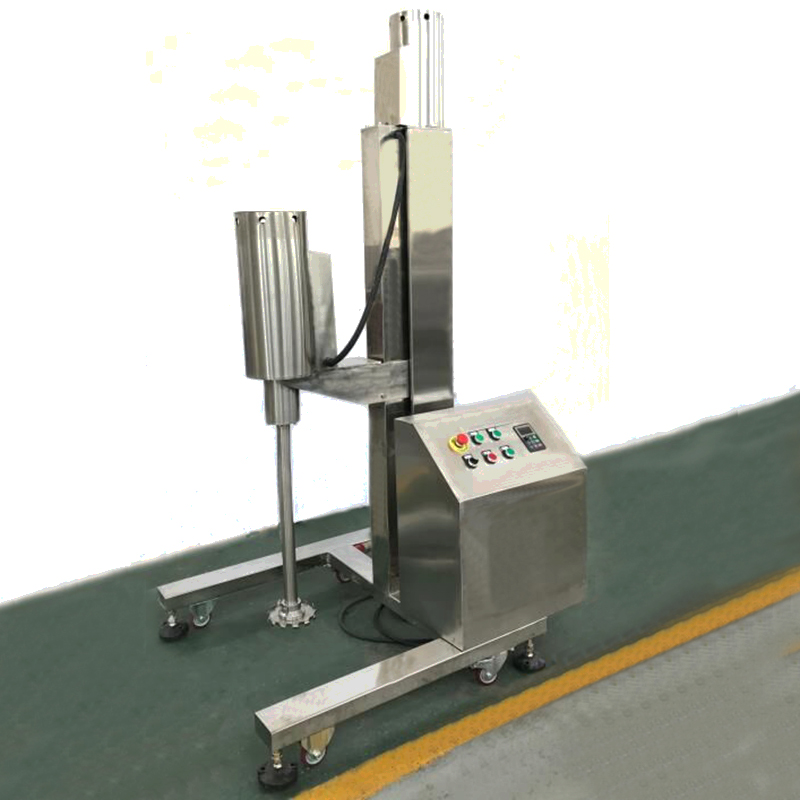

High Shear Dispersing Mixer for Powder and Liquid

Product Description:

Detail Description

Range of application Dispersion machine, also known as a blender. According to lift form that can be divided into the different hydraulic lift dispersion machine, pneumatic elevation dispersion machine and mechanical lifting dispersion machine. Widely used in the coatings, printing ink, paint, adhesives and other chemical products. This machine by the hydraulic system, main drive, mixing system, steering mechanism, electric cabinet of five parts, each part of the structure is compact, is reasonable. Scattered disc type: flat saw type, three righteousness paddle, dish and other forms.

The main features:

A, dispersion machine adopts stepless speed regulation: with electromagnetic speed control, frequency control of motor speed, such as used for water-based coating and explosion-proof variable frequency speed regulation (such as for oily coating), and other forms. Stepless speed regulation function can fully meet the technological process of different process requirement, can choose according to different stages of process different rotational speed. Powder without additives, the crystal package integrity materials shall not apply to the high demand.

Second, dispersion machine below the dispersion plate is laminar state, different flow velocity of pulp layer diffusion, dispersion effect. High-speed dispersion machine has the hydraulic elevator, 360 degrees of rotation, stepless speed regulation and other functions. Can configure 2-4 containers only at the same time, hydraulic lift travel 1000mm,360 degree rotation function can better meet multi-usage, can in a very short period of time from one shift to another cylinder for homework, dispersion machine greatly improves the work efficiency, but also reduces the manual labor intensity.

Quick View -

MZH-M Cream paste Homogenizer Mixer

Product Application

This machine is the our product newly developed by technology from Germany, it is refer to the Mixer of the Germany specialty technology which have the accurate date theory, ensure the tiptop cut off frequency, the least disperse grain, the preeminence quality.

Main Features

The mixer which together with manual/hydraulic lift mechanism and suit for moveable installation, that is easy to operate. The mixer costs you less and makes you big profits and can be used to operate on a variety of materials.

It can not only be used separately but also be used in combination with other equipment. Stainless steel is used to prevent the mixer from being corroded by erosion materials. And with the seal sleeve on the main shaft, the mixer is capable of working in vacuum, while it is being cooled by water during operation.Applicable: cosmetics, emulsion, bath shampoo, ointment, tooth paste, oil, perfume, beverage, pharmaceuticals, coating and adhesive.

Quick View -

Factory price stainless steel reverse osmosis water treatment

Product Description

I. Technical process

Tap water→booster pump→sand filter→carbon filter→5µS security filter→

high pressure pump→stainless steel pump→500L/H RO system→ well water

II. Configuration

A. Two stainless steel 304 barrels attached American auto device

B. Equipped with booster pumps, stopped automatically when there is no water

besides it will add pressure when low pressure.

C. High pressure pump. Imported solenoid valve. Imported DOW membrane,

whose unit desalination rate is 99%. The whole set is 97%-98%.

D. Pressure protection device imported from Korea which used to protect the

high pressure pump.

E. Membrane automatic rinse as the machine is operated, digital time control

F. Fully automatically feeding water G. Raw water conductivity≤400us/cm, well water conductivity≤10us/cm

Quick View

What we are about

We are a new high-tech company with a combination of design, manufacture, consultation and sale. Taking advantage of the professional standards and mechanical Engineering mellow technology in the field of chemical machinery, Now, This company is making great progress..

Follow us on:

Reviews

There are no reviews yet.