MZH-F Aerosol production line machine filling spray cans

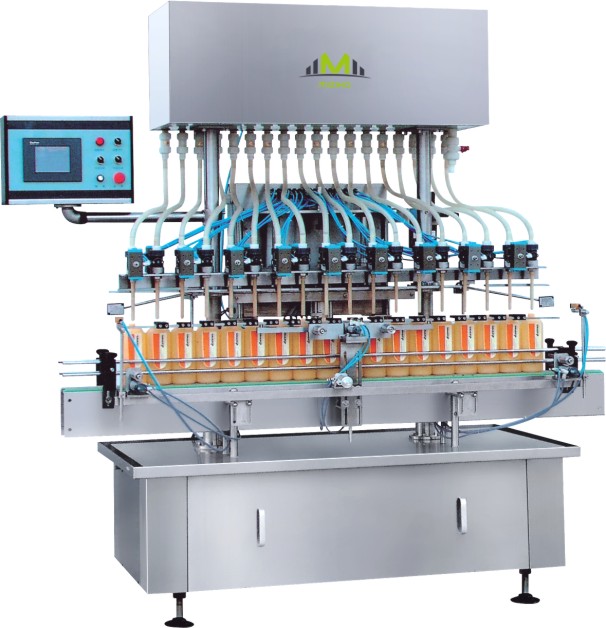

The machine is composed of automatic aerosol filling production line.Liquid filling, filling and sealing in the same production line.High speed, high precision and good stability.Suitable for medium and large enterprises.

Description

MZH-F Aerosol production line machine filling spray cans

The machine is droved by an Ex-proof motor for the cans transportation and positioning, with this machine, there will be no squeezed cans, blocked cans or inverted cans. The speed can be adjusted freely and steplessly.

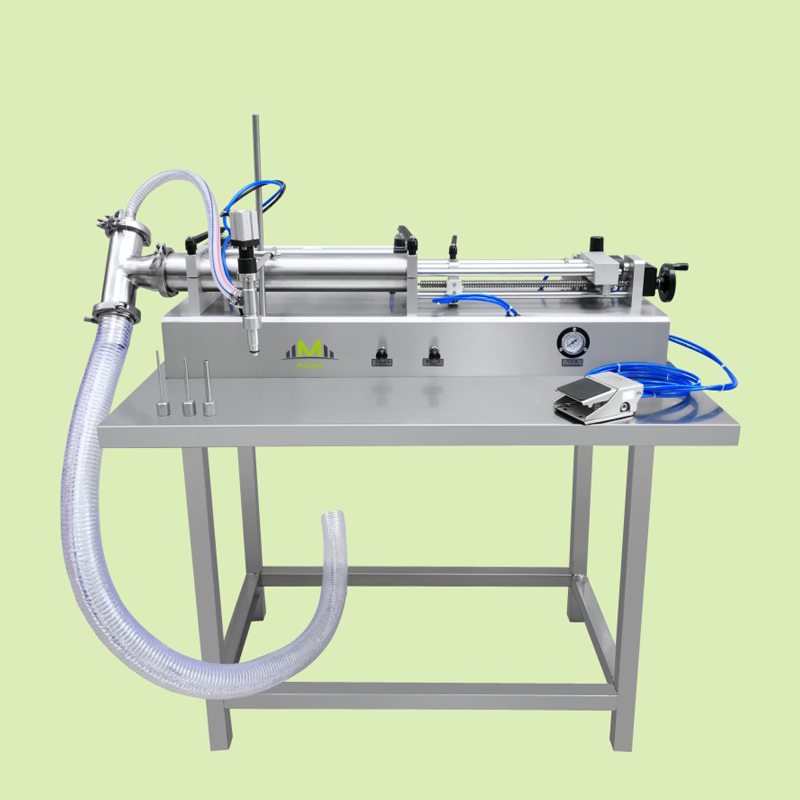

It is provided with 3 liquid filling heads, all are under pneumatic control, and each head can be controlled separately; main pneumatic control devices are imported from Italy. It features that no material is charged in absence of aerosol cans.

The turntable selects and transfers the valves to production line with the compressed air, inserting valves into cans and seal reliably.This machine has high sealing quality, it saves labors and increase productivity.

It is provided with 1 sealing head, 3 gas filling heads, 2 booster pumps, as well a gas storage tank with an energy accumulator; full pneumatic control with main parts are imported from Italy or Japan. It has the feature that guiding devices are provided at both sealing head and inflating heads, reliable sealing quality, less leakage of gas inflating. Advise: build a filling room, to enhance security and reduce the risk of explosion.

This machine places the actuators to the cans and press automatically

The vibrating coil will arrange the caps automatically, sending the capers to the automatic pressing machine. The machine can increase the automation and reliability of the line, increase the productivity.

Including star wheel and guide plate for liquid filling station, sealing & gas filling station, actuator presser station and cap presser station for different diameter 57mm & 65mm

This part is for different shape actuator or cap

These are the auxiliary parts of the automatic filling line.

Reviews

There are no reviews yet.