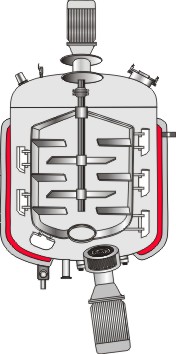

MZH-500L liquid washing homogenizing mixer

Technical parameters:

Volume (L): 500

Stirring power (kw): 2.2

Stirring speed (r/min): 0-65

Homogeneous power (kw): 5.5-7.5

Homogeneous rotational speed (r/min): 3000

Heating mode: steam or electric heating (optional)

Note: the data parameters of this device are inconsistent with technical improvement and customization.

Description

MZH-500L liquid washing homogenizing mixer

The liquid washing homogenizing mixer produced by our company is mainly suitable for the configuration of detergent (such as shampoo, detergent, shampoo, bath dew and so on). The mixer has the functions of mixing, dispersing, heating, cooling, pumping material and defoaming (type selection). It is an ideal equipment for the domestic plant to be equipped with washing.

It is mainly used for the preparation of liquid detergent (such as detergent, shampoo, shower gel, laundry detergent, etc.), and can also be used for other liquid liquid, liquid solid mixing.

1, AES dissolving machine: self suction continuous, domestic initiative, patent protection.

2, High speed dispersing plate: strong mixing, dispersing viscous, solid liquid materials.

3, scraper agitator: effective and rapid realization of macro mixing, product molding.

In the lotion production, AES, AESA, LSA and other raw materials are quickly dissolved into 25-30% solution, saving energy consumption, shortening the production cycle and accurately measuring.

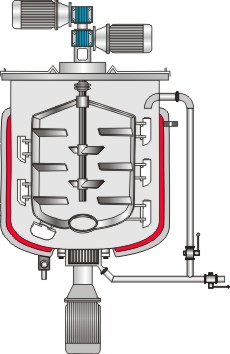

USAGE

This unit is available for manufacturing liquid products (such as detergent, shampoo, shower gel, etc.), it integrates mixing, homogenizing, heating, cooling, pump discharging finished products and defoaming (optional) functions. It is the ideal equipment for liquid products in domestic and international factories.

PERFORMANCE & CHARACTERISTIC

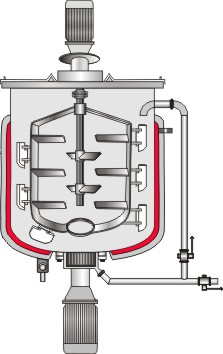

◆The wall scraping mixer adopts frequency converter to adjust the mixing speed which would make various kinds of products according to the customers’ requirements.

◆The diversified high speed homogenizer can powerfully mix solid liquid products and dissolve the material like AES, AESA, LSA etc. it save energy consumption and shorten the production time.

◆The pot body is welded with three layers imported stainless steel. The whole machine and pipes are mirror polished which is definitely satisfied with the GMP standard.

◆According to different processing, the main pot can be heated and cooled down. steam heating or electric heating. Discharge from the bottom by the homogenizer or by a transfer pump.

Reviews

There are no reviews yet.