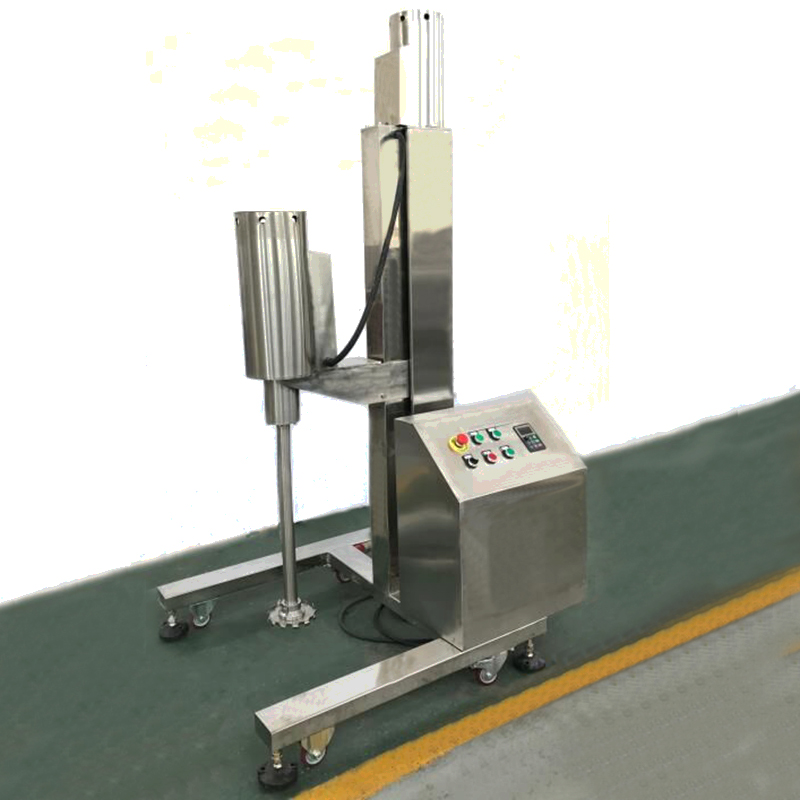

Moveable Stainless Steel Pneumatic High Speed Lifting Disperser(Different Motor Power)High Shear Disperser mixer homogenizer

this company produces the vacuum emulsifying type varieties diverse, including homogeneous system points on homogeneous under homogeneous, both inside and outside circulation homogeneous, mixing system and two-way one-way stirring, ribbon stirring;The lifting system is divided into single cylinder and double cylinder lifting, and can be customized according to customer request a variety of meets the demand of high quality products.

Description

Moveable Stainless Steel Pneumatic High Speed Lifting Disperser(Different Motor Power)High Shear Disperser mixer homogenizer

![]()

Performance and Characteristics

♦ this company produces the vacuum emulsifying type varieties diverse, including homogeneous system points on homogeneous under homogeneous, both inside and outside circulation homogeneous, mixing system and two-way one-way stirring, ribbon stirring;The lifting system is divided into single cylinder and double cylinder lifting, and can be customized according to customer request a variety of meets the demand of high quality products.

♦ triple mixing adopt imported frequency converter speed control, can meet different process requirements;

♦ homogeneous structure of German technology, using imported double mechanical seal effect, emulsifying speed can reach 4200 r/min, highest the highest shear fineness can reach 0.2 5 um;

♦ vacuum deaeration to achieve aseptic requirements, and USES the vacuum materials, especially for powder material using vacuum suction to avoid dust float in the sky;

♦ main pot pot can choose lifting device, convenient cleaning, cleaning effect is more significant, the pot body can choose dumping of discharge;

♦ pot body adopted three layers of imports of stainless steel plate welding, tanks and pipelines for mirror polishing, full compliance with GMP requirements;

♦ according to the technological requirements, heating and cooling material of tank, steam and electric heating two heating methods mainly include;

♦ in order to ensure the whole machine control is more stable, using imported electrical appliances, can fully meet international standards;

Technicial Parameters

|

Model&Valume |

Homogenizer Motor |

Stirrer Motor |

Overall Dimension |

Power |

Ultra Vacuum |

|||

|

kw |

r/min |

kw |

r/min |

L*W*H/wholeH |

Steam heater |

Electric heater |

Mpa |

|

| MZH-10L |

0.75 |

0-3000 |

0.37 |

0-63 |

1300 |

580 |

1600/1950 |

3 |

| MZH-50L |

3-5.5 |

0-3000 |

1.1 |

0-63 |

2600 |

2250 |

1950/2700 |

9 |

| MZH-100L |

4-7.5 |

0-3000 |

1.5 |

0-63 |

2750 |

2380 |

2100/2950 |

13 |

| MZH-200L |

5.5-11 |

0-3000 |

2.2 |

0-63 |

2750 |

2750 |

2350/3350 |

15 |

| MZH-300L |

7.5-11 |

0-3000 |

2.2 |

0-63 |

2900 |

2850 |

2450/3500 |

18 |

| MZH-500L |

1-11 |

0-3000 |

4 |

0-63 |

3650 |

3300 |

2850/4000 |

24 |

| MZH-1000L |

1-15 |

0-3000 |

5.5 |

0-63 |

4200 |

3650 |

3300/4800 |

30 |

| MZH-2000L |

15 |

0-3000 |

7.5 |

0-63 |

4850 |

4300 |

3800/5400 |

40 |

Reviews

There are no reviews yet.