Machine to make perfume

This machine adopts imported parts, piston and cylinder which made of stainless steel and polytetrafluoroethylene. Excellent qualified imported components and perfect mechanical design ensure its leading position among domestic similar machine.

The new vertical design, light and easy to operate.

Description

Machine to make perfume

Machine to make perfume

MZH-F Perfume Vacuum filling machine

Perfume filling machine is suitable for filling perfume and other water-based materials. The machine is filled with negative pressure and fixed liquid surface.

Perfume filling machine features:

1, negative pressure liquid absorption filling, product filling amount is measured by liquid surface height.

2, with a foot wheel, easy to move.

3, contact parts and mesa with 304 stainless steel material.

4, suitable for glass bottles, or vacuum bottles after not easy deformation of plastic bottles.

5. It is convenient to adjust, operate and maintain.

I. Characteristics

1. This machine adopts imported parts, piston and cylinder which made of stainless steel and polytetrafluoroethylene. Excellent qualified imported components and perfect mechanical design ensure its leading position among domestic similar machine.

2. The new vertical design, light and easy to operate.

3. Switch function between manual and automatic: when machine is in “automation” condition, machine will fill continuously with set speed: when it is under “manual” condition, operator step on footplate to realize filling. If stepping footplate continuously, it will change to continuous filling condition. Cylinder and three-way parts use cuff connection which is easy to remove. It does not need any special tools so it is easy to clean.

4. Anti-leaking filling system: the closure head is moved when the cylinder moves up an down during filling. When the closure head down by cylinder,, then valve will open and start to fill material; when it up by cylinder, valve will close and stop to fill and avoid leaking and wire drawing.

5. It can fill most of liquid, chemical, pharmaceutical, cosmetic, food and other industries.

II. Techical Specifications

|

Model |

MZH-F4 |

|

Air Pressure |

>0.7MPa |

|

Pressure of Reducing Valve |

0.55-0.65MPa |

|

Air Consumption |

0.3 m3/min |

|

Capacity |

20-40 time/min |

|

Filling Range |

10-1500ml |

|

Precision |

±1.5g |

|

Power consumption |

0.55KW |

|

Use bottle heigh |

250mm (customized) |

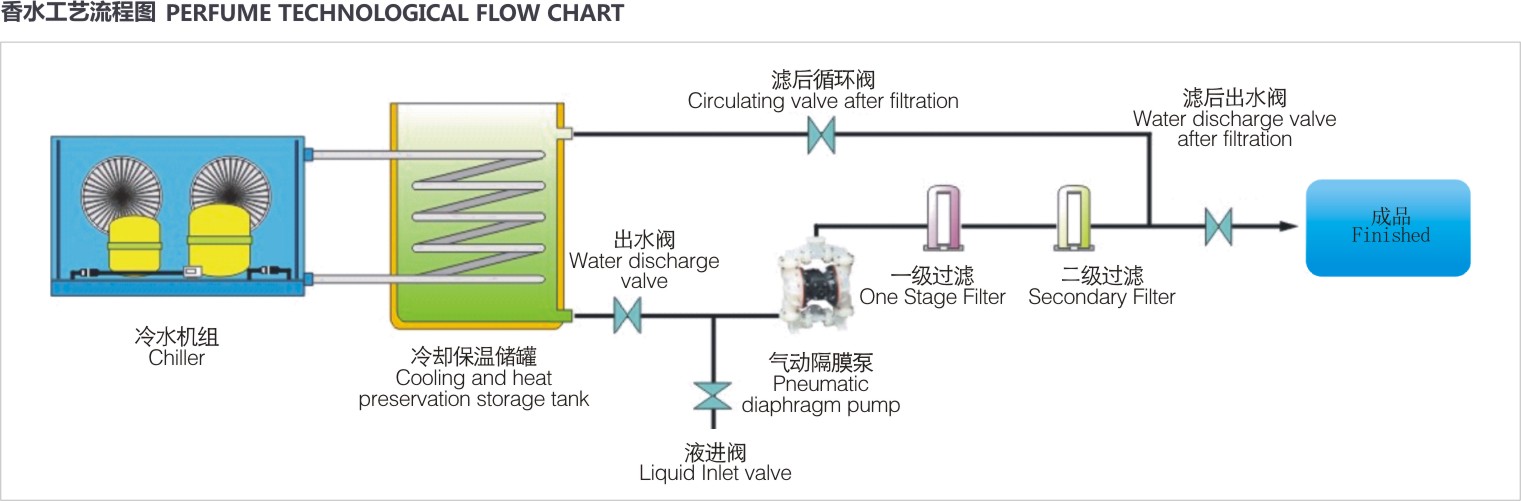

MZH-PM PERFUME FREEZING MACHINE

Perfume refrigerator

Technical parameters of 100L perfume refrigerators:

Freezing power (P): 3

Freezing capacity (L): 100

Filtering precision (mu m): 1-0.1

The perfume freezing filtration device is an ideal equipment for our company to introduce advanced technology from Germany to make-up water and perfume. The products are made of high quality 316L stainless steel and imported pneumatic diaphragm pump from the United States as pressure source for positive pressure filtration. The connecting pipes are made of hygienic polishing tubes, which are all installed in a quick assembling way to facilitate disassembly and cleaning. The use of polypropylene microporous filter membrane is widely used in the cosmetics industry, scientific research department, hospital, laboratory and other units for a small amount of liquid clarification and bactericidal filtration, or microchemical analysis, convenient and reliable.

Standard configuration

1, stainless steel insulation tank and titanium metal coil

2, ultra low temperature refrigerating unit (import)

3. Anticorrosive pneumatic diaphragm pump (import)

4, polypropylene microporous ultrafiltration membrane

5, stainless steel moving bracket

Sealed type electronic control system and sanitary pipe fittings valve

MZH-perfume wrapping machine

Reviews

There are no reviews yet.