We shipp to all the world

You can get our machine either through air or sea.

Up to 10% off the bill

Contact us to know more about our special offers.After service

Our team will follow you until you master the machineManuals

With the training we provide you manuals supported with videosLiquid spray products 3 in 1 aerosol filling machine

Machine Instruction:

This machine is made from the former semi-automatic aerosol filling machine.It assemble the liquid filling, inflate and seal on the same table, it needs only one worker to operate it.It has high speed, high-accuracy and good stabilization.Good choice for the medium sized and small-scale company.

Description

Liquid spray products 3 in 1 aerosol filling machine

Technical Parameters:

|

Filling Capacity: |

30-500ml |

|

|

Capping Dia. (mm) |

Φ26.5-Φ27.5 |

|

|

Capping Depth. (mm) |

5.0-6.0 |

|

|

Aerosol Can Applied |

Heigh |

80-315mm |

|

Dia |

35-70mm |

|

|

Filling Accuracy : |

≤±1% |

|

|

Max. liquid filling capacity |

500ml |

|

|

Working pressure |

0.50-0.70Mpa |

|

|

Max. exhausting |

0.6m3/min |

|

|

Producing Speed : |

800-1200cans/h |

|

|

Sizes |

1200×650×1600mm |

|

|

Suitable Valve: |

1″ |

|

|

Weight |

250KG |

|

Related Products

-

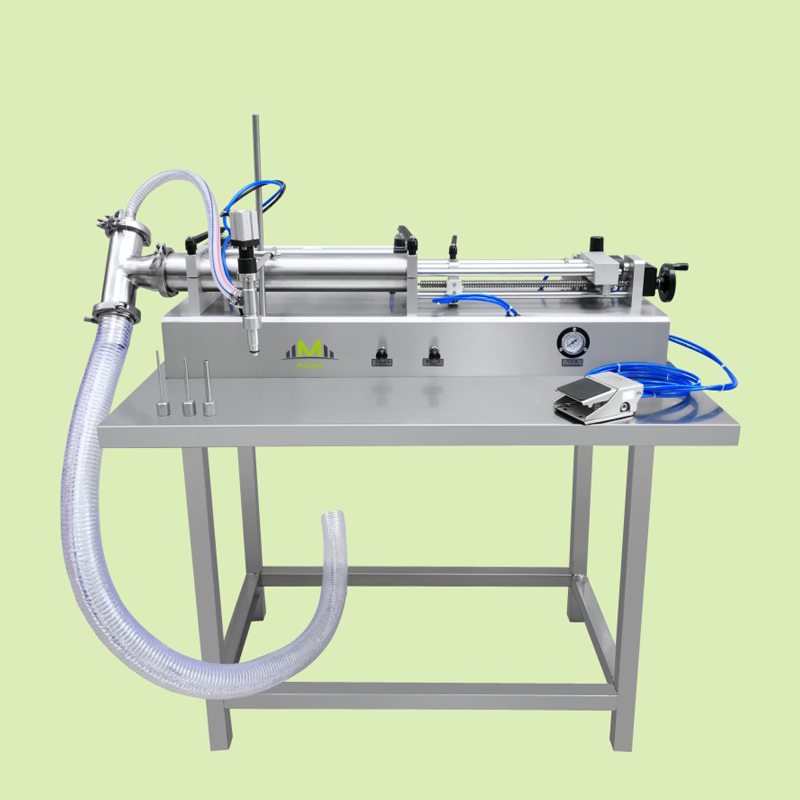

MZH-F Semi automatic liquid filling machine

1.the new design, light and convenient, can automatically draw the material (liquid), exempt from hopper frequent charging trouble;

2.manual and automatic switch to each other, as well as artificial foot filling, but also mechanical automatic filling; Material cylinder, tee part adopts fast connection, convenient disassembly, convenient cleaning, comply with GMP standardVoltage: 0 v

Power: 0 w

Quick View -

MZH-SY 5-100ml pneumatic shampoo yogurt paste cosmetic cream honey filling machine

-

MZH-TFS Semi-automatic filling and capping machine

-

Automatic 12 Holes stainless steel lipstick filling machine cosmetic machinery

Product Application:

1)The machine is designed pointed to liquid cosmetics,i.e.lipstick,pencil lipstick,brow pencil,lip oil,lip balm…etc

2)Individual object barrel stirring and temperature control design,meet the requirements of varieties of raw materials.

3)It adopts advanced automization technics (human machine interface,PLC program control), parameters including time and temperature control from the whole machine needing to set all is completed by human machine interface.

Simplify operating system program and make the machine function stabler.4)The machine adopts aluminum extrusion construction,easy to clean on the aluminum station.

5)System operation program is simple,it does not take time to educate and train.

6)Every unit (including object barrel,pump,object tube,nozzle)all adopts intelligent temperature control individually,temperature control precision is ±0.3℃,make the equipment easier operate.

7)Auto-counter.

Quick View -

1.00 out of 5

MZH-F Liquid filling machine with heater and mixer

This machine is suitable to measurably fill the ointment materials with high viscosity and poor flow ability.It does the filling pneumatically, its hopper and the cylinder both are thermally preserved with electrically heated circulating water.The hopper is equipped with a frame mixing system.

Quick View

What we are about

We are a new high-tech company with a combination of design, manufacture, consultation and sale. Taking advantage of the professional standards and mechanical Engineering mellow technology in the field of chemical machinery, Now, This company is making great progress..

Follow us on:

Reviews

There are no reviews yet.