Automatic Induction sealing package machine

MZH-900 series plastic packaging machine suitable for sealing, adopts electronic constant temperature control and stepless speed transmission mechanism, automatic and continuous sealing materials of plastic film, According to the need to also can configure creasing printed wheel and counting device.

Description

MZH-SP2100 Automatic Inductor Aluminum Foil Sealing Machine

General Description

Electromagnetic-induction sealing technology for composite materials is an internationally approved up-to-date sealing means. Its characteristic of non-contact heating applies to sealing of plastic (PP/PVC/PET/ABS/HDPE/PS/ DURACON) bottles, glass bottles and all kinds of composite plastic hoses. It is the most advanced bottle sealing technology for medicines, foods, oils and greases, daily chemicals, pesticides and fertilizers, etc.

Operating Principles

The frame sends supersonic current to a sensor under which an aluminum foil at the bottle neck heats quickly so that the composite film on it melts and binds together with the neck to achieve efficient and perfect sealing effect and extend the quality guarantee period of products.

Features

Its display indication of operating voltage and current is visibly legible. 304stainless steel exterior..

Its adjustable knob and button type switches are easy to operate.

Its automatic protection against excessive current and voltage is safe and reliable.

The height of its sealing tip is easy to adjust using a hand wheel.

It features good quality as well as an air cooling effect close to that of a water cooled unit.

It is characterized by high sealing rate and reliable performance. An optional no-foil detecting eliminator is available upon user`s request

Scope of Applications

It may be used for the aluminum foil sealing of all kinds of round, square and special-shaped bottles for foods, medicines, cosmetics, daily chemicals, etc.

Its high sealing rate can meet the requirement for mass production.

Its split structure allows use of a conveyor in combination or aluminum foil sealing on the original production line.

The type of the sealing tip (plate or tunnel type) may be customized upon user`s request.

Technical Parameter

| Power supply | AC220V 50/60Hz |

| Max power | 2100W |

| Sealing dia (Optional) | 50-120mm |

| Conveyor Belt speed | 12.5M/min |

| Sealing machine | polyethylene bottle with bottle mouth dia 35mm, bottle bottom dia 40mm |

| Speed | 0-260bottles/Minute |

| Cooling way | Air cooling |

| Sealing height | 20-350mm |

| Bottle height | 20-400mm |

| Working way | Continuous working |

| Material | Stainless steel |

| Machine dimension (L*W*H) | 1400×470×1300(mm) |

| Packing dimension(L*W*H) | 1450×1400×420(mm) |

| Net Weight | 62kg |

-

MZH-900 Continuous Sealing Machine Horizontal

DESCRIPTION

MZH-900 series plastic packaging machine suitable for sealing, adopts electronic constant temperature control and stepless speed transmission mechanism, automatic and continuous sealing materials of plastic film, According to the need to also can configure creasing printed wheel and counting device.

TECHNICAL SPECIFICATIONS

| Model | MZH-900 |

| Voltage | AC 220V/50Hz 110V/60HZ |

| Motor Power | 50W |

| Sealing Power | 300×2W |

| Speed | 0-12(0-16)m/min |

| Sealing Width | 8mm 10mm |

| Temperature Range | 0-300℃ |

| Printing Type | Steel wheel creasing

(optional) |

| Distance from sealing Center to the Conveyor | 10-14mm |

| Conveyor Size | 840×180mm |

| Max. Conveyor

Loading for Single Bag |

≤1kg |

| Overall conveyor Loading | ≤3kg |

| Overall Dimension | 840×380×270mm |

| Net weight | 32kg |

-

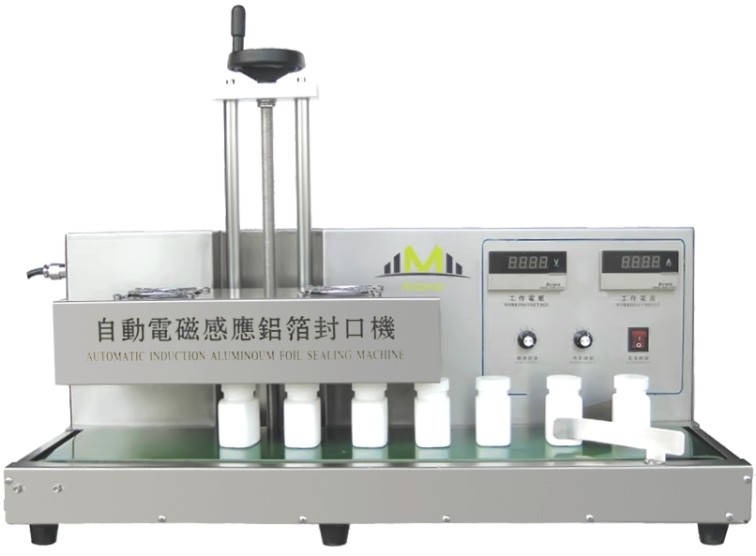

Desktop Automatic Electromagnetic Aluminum Foil Sealing Machine

Feature

- Its operating voltage and current are indicated by pointers. 304 stainless steel exterior.

- Its adjustable knob and button type switches are easy to operate.

- Its automatic protection against excessive current and voltage is safe and reliable.

- The height of its sealing tip is easy to adjust using a hand wheel.

- Its high sealing rate can meet the requirement for mass production.

The machine is highly functional and can continuously operate with a conveyor belt and a bottle feeding platform.

Scope of Applications

- Designed for aluminum foil sealing of φ15-60mm bottles, MZH-1300 is highly economically applicable.

- With a belt and a no-foil bottle eliminating mechanism, MZH-1600 is applicable for the products requiring high sealing quality.

- Using unique ultra-big-diameter sealing technology, MZH-1800 is designed for sealing of bottles with a big neck.

Technical Data

| Items | MZH-1300 | MZH-1600 | MZH-1800 |

| Power supply | AC220V 50/60Hz 2000W | AC220V 50/60Hz 2500W | |

| Sealing diameter (optional) | φ15-60mm | φ15-121mm | |

| Sealing rate | 0-280 bottles/min | 0-80 bottles/min | |

| Conveyor belt speed | 0-12.5m/min | 0-8.5m/min | |

| Ceiling height | 20×180mm | 20×240mm | |

| Dimensions of mainframe | 805×395×330mm | 1005×440×390mm | |

| Packing size | 970×515×475mm | 1305×510×445mm | 1115×550×495mm |

| Weight | 34㎏ | 39㎏ | 51㎏ |

-

Handheld Electromagnetic-induction Aluminum Foil Sealing Machine

Feature

- PLC control, operational memory and data saving, adjustable sealing duration and power, and overload protection.

- Injection-molded chassis touch screen and high-brightness digital display.

- Handholding handle and manual control for easy operation.

Scope of Applications

- MZH-1000 is designed for aluminum foil sealing of large-diameter bottles.

- MZH-1010 is applicable for aluminum foil sealing of φ15-50 bottles.

- MZH-1020 is designed for sealing of small-diameter bottles.

Technical Data

| Items | MZH-1000 | MZH-1010 | MZH-1020 |

| Power supply | AC220V 50/60Hz 2000W | AC220V 50/60Hz 1300W | |

| Sealing diameter | φ15-121mm | φ15-50mm | φ15-30mm |

| Sealing rate | 0-30bottles/min | 0-40bottles/min | |

| Dimensions of mainframe | 350×270×100mm | ||

| Packing size | 522×435×240mm | 450×415×175mm | |

| Weight | 6㎏ | 3.4㎏ | 3.5㎏ |

Reviews

There are no reviews yet.