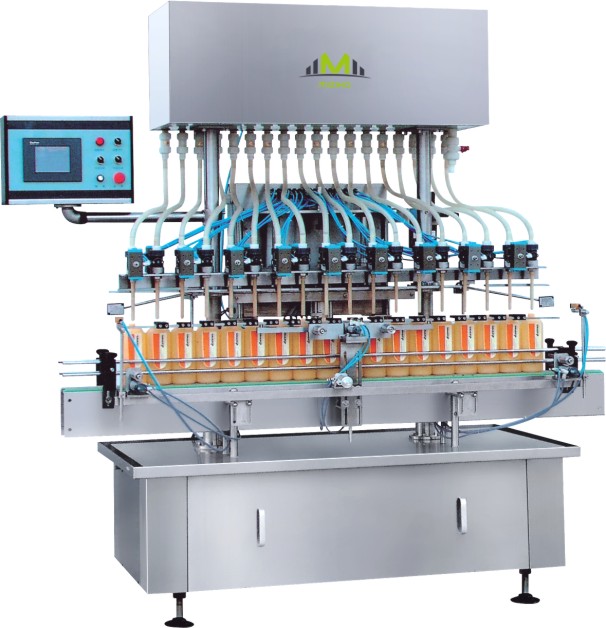

Automatic liquid filling machine

This is full automatic filling machine for Food,Cosmetic and Pharmacy products.

It can fill food material as Oil,Liquids sauce,Ketchup,Honey,Salad dressing,Soybean.

It can fill Cosmetic material as Paste,Skin care,Shampoo, Lotion,Shower,Cream.etc.

It can fill Pharmacy material as Ointment,Disinfectant fluid,Cough syrup,other liquid medicine.

Description

Automatic liquid filling machine

Characteristic

1.The contact material is SUS316L/SUS304 and others are SUS304 stainless steel.

2.The machine include bottle turn table,filling,capping, labeling,print date,Container machine etc.

3.It has intuitive and convenient operation, measuring accurate, positioning precision.

4.Fully in accordance with the GMP standard production and passed CE certification.

5.No bottle no filling.

| 1. Main machine: | Feed bottle table and 2 filler。 |

| 2. Working way | The introduction of foreign technology development of new varieties, the use of the disc pilot bottle, frequency control, clutch kill car. |

| 3. Characteristic: | Turntable is a power table with variable frequency and speed regulation, they can cooperate with the conveyor belt to help you easily finish the work of the bottle and the bottle. |

| 4. Manipulation: | The frame parts are made of high quality 304 stainless steel material, high strength tempered glass desktop after polishing treatment, to ensure the smooth running of the bottle. Variable speed control, reverse rotation and adjust the height, so that you operate more convenient. |

| 5.Structure | Compact structure, small occupied area, the length is less than 1.2 meters, width 1.2 meters, height less than 1 meters. |

| 6. Adaptability bottle | Not applicable to the opposite sex bottle, the opposite sex bottle needs special. |

| 7. Guarantee: | All parts are guaranteed for one year from the date of arrival (except wearing parts) |

| 8. Voltage: | 220V |

| 9. Weight: | 380kg |

Bottle feeding table machine description

| Feeding bottle table | |

| 1. Including: | Bottle feeding machine。 |

| 2. Operation mode | The introduction of foreign technology development of new varieties, the use of the disc pilot bottle, frequency control, clutch kill car. |

| 3. Characteristic | Turntable is a power table with variable frequency and speed regulation, they can cooperate with the conveyor belt to help you easily finish the work of the bottle and the bottle. |

| 4. Manipulation: | The frame parts are made of high quality 304 stainless steel material, high strength tempered glass desktop after polishing treatment, to ensure the smooth running of the bottle. Variable speed control, reverse rotation and adjust the height, so that you operate more convenient. |

| 5. Structure | Compact structure, small occupied area, the length is less than 1.2 meters, width 1.2 meters, height less than 1 meters. |

| 6. Adaptability bottle | Not applicable to the opposite sex bottle, the opposite sex bottle needs special. |

| 7. Guarantee | All parts are guaranteed for one year from the date of arrival (except wearing |

| 8. Voltage | 220V Single phase |

| 9. Weight | About 80kg |

III. Manin parts brand

| No | Name | Brand | Original |

| 1 | Enter the bottle photoelectric | Kean scholar | Japan |

| 2 | Filling main cylinder | AirTAC | Taiwan |

| 3 | Nozzle cylinder | AirTAC | Taiwan |

| 4 | Touch screen | Siemens | Taiwan |

| 5 | PLC | Siemens | Japan |

| 6 | Conveying motor | Tianmai | China |

| 7 | Frequency converter | Delta | Taiwan |

| 8 | Solenoid valve | AirTAC | Taiwan |

| 9 | Electric appliance | Schneider | |

| 10 | Material contact material | 316 Stainless steel | China |

| 11 | Non material contact material | 304 stainless steel chrome optical axis PP, POM, anodic aluminum oxide | |

MZH-F 6 heads full-automatic liquid paste filling machine

Technical parameter:

Filling range (ML): 50-500 100-1000 250-2500 500-5000

Production capacity (bottle / hour): 2600-2900, 2600-2900, 2200-2600 2200-2600

Filling speed: adjustable

Filling precision: less than 1%

Gas pressure (MPa): 0.6-0.8

Note: if filling is done by servo filling, the measuring accuracy can reach + 0.5%, and the filling speed can be adjusted at will, and the filling range is larger.

The full automatic multi head green cover straight line filling machine is a kind of high and new technology filling equipment which is programmed by PLC, photoelectric sensing and pneumatic. It is widely used in liquid filling of soy sauce, vinegar, liquor, alcohol, reagents, washing liquid, disinfectant, lubricating oil and cosmetics. Accurate filling measurement, no bubble, no drip leakage. It can be applied to filling various bottle shapes (including special bottles) of 100-2000ml.

The multi head automatic liquid filling machine is a new generation of automatic filling machine developed by our company for many years and has absorbed the advanced technology of the world. The electrical and pneumatic components are selected by the world famous brand. It is controlled by PLC and the human-machine interface. It has the features of novel design, beautiful appearance, friendly interface, strong adaptability, simple operation, accurate filling and easy maintenance. Widely used in food and beverage, brewing, medicine, condiment, tofu, jelly, Boudin, juice, milk, lactic acid milk, cold drinks and other industries.

Note: filling range and speed can design different filling heads according to user needs.

advanced design

- The machine is suitable for filling different specifications of containers, and can switch the filling specifications in a few minutes.

2, the filling cycle is short and the production capacity is high.

3, replace the filling specifications do not need to add spare parts, only to make adjustments can be completed.

4, users can choose the filling quantity according to their production capacity to determine the number of filling heads.

- Touch operation color screen, which can show the production status, operation procedures, filling methods and so on.

6, each tin can be equipped with a bottle mouth device to ensure accurate positioning of the injection material.

unique measurement method

1, the design adopts linear grouping bottles and bottles, and makes the filling function expand. All kinds of containers can be effectively filled in this equipment.

2, choose the international advanced pneumatic filling valve to ensure that there is no leakage and no saliva in the filling process.

3, powerful PLC software support, can achieve the ideal filling operation.

4, human-machine friendly interface, all operations are done on touch color screen.

accurate measurement control

1, filling adopts fixed channel parameters to control filling time to achieve different metering filling.

- The precise time of filling the pneumatic valve can be set to 0.01 seconds. It can control the measurement accuracy in the range of + 1% error, reduce unnecessary material consumption and improve the economic benefits of users.

3, the design of each filling head can be adjusted individually to achieve consistency in filling measurement.

4, the machine set the bottle counting program, no bottle, the count is not in place, not filling, only when the number of bottles recorded by the counter and the set filling number is only started filling;

5, the amount of filling can be adjusted to meet the needs of the amount of filling, then fine tuning, you can get the ideal filling measurement accuracy.

MZH-F 2nozzles full-automatic liquid paste filling machine

Filling machine description

Introduce:

This is full automatic filling machine for Food,Cosmetic and Pharmacy products.

It can fill food material as Oil,Liquids sauce,Ketchup,Honey,Salad dressing,Soybean.

It can fill Cosmetic material as Paste,Skin care,Shampoo, Lotion,Shower,Cream.etc.

It can fill Pharmacy material as Ointment,Disinfectant fluid,Cough syrup,other liquid medicine.

Characteristic

1.The contact material is SUS316L/SUS304 and others are SUS304 stainless steel.

2.The machine include bottle turn table,filling,capping, labeling,print date,Container machine etc.

3.It has intuitive and convenient operation, measuring accurate, positioning precision.

4.Fully in accordance with the GMP standard production and passed CE certification.

5.No bottle no filling.

| 1. Main machine: | Feed bottle table and 2 filler。 |

| 2. Working way | The introduction of foreign technology development of new varieties, the use of the disc pilot bottle, frequency control, clutch kill car. |

| 3. Characteristic: | Turntable is a power table with variable frequency and speed regulation, they can cooperate with the conveyor belt to help you easily finish the work of the bottle and the bottle. |

| 4. Manipulation: | The frame parts are made of high quality 304 stainless steel material, high strength tempered glass desktop after polishing treatment, to ensure the smooth running of the bottle. Variable speed control, reverse rotation and adjust the height, so that you operate more convenient. |

| 5.Structure | Compact structure, small occupied area, the length is less than 1.2 meters, width 1.2 meters, height less than 1 meters. |

| 6. Adaptability bottle | Not applicable to the opposite sex bottle, the opposite sex bottle needs special. |

| 7. Guarantee: | All parts are guaranteed for one year from the date of arrival (except wearing parts) |

| 8. Voltage: | 220V |

| 9. Weight: | 380kg |

- Bottle feeding table machine description

| Feeding bottle table | |

| 1. Including: | Bottle feeding machine。 |

| 2. Operation mode | The introduction of foreign technology development of new varieties, the use of the disc pilot bottle, frequency control, clutch kill car. |

| 3. Characteristic | Turntable is a power table with variable frequency and speed regulation, they can cooperate with the conveyor belt to help you easily finish the work of the bottle and the bottle. |

| 4. Manipulation: | The frame parts are made of high quality 304 stainless steel material, high strength tempered glass desktop after polishing treatment, to ensure the smooth running of the bottle. Variable speed control, reverse rotation and adjust the height, so that you operate more convenient. |

| 5. Structure | Compact structure, small occupied area, the length is less than 1.2 meters, width 1.2 meters, height less than 1 meters. |

| 6. Adaptability bottle | Not applicable to the opposite sex bottle, the opposite sex bottle needs special. |

| 7. Guarantee | All parts are guaranteed for one year from the date of arrival (except wearing |

| 8. Voltage | 220V Single phase |

| 9. Weight | About 80kg |

III. Manin parts brand

| No | Name | Brand | Original |

| 1 | Enter the bottle photoelectric | Kean scholar | Japan |

| 2 | Filling main cylinder | AirTAC | Taiwan |

| 3 | Nozzle cylinder | AirTAC | Taiwan |

| 4 | Touch screen | Siemens | Taiwan |

| 5 | PLC | Siemens | Japan |

| 6 | Conveying motor | Tianmai | China |

| 7 | Frequency converter | Delta | Taiwan |

| 8 | Solenoid valve | AirTAC | Taiwan |

| 9 | Electric appliance | Schneider | |

| 10 | Material contact material | 316 Stainless steel | China |

| 11 | Non material contact material | 304 stainless steel chrome optical axis PP, POM, anodic aluminum oxide | |

MZH-Detergent Filling machine

Introduce:

The Detergent Filling machine is a high-tech product researched and developed by our company. It is suitable for products of various viscosity such as liquid sauce, ketchup, honey wine,It is widely applied for filling of products in such industries as food, cosmetics, medicine,grease,daily chemical industry, detergent, pesticide and chemical industry etc.

Characteristic

1.The contact material is SUS316L/SUS304 and others are SUS304 stainless steel.

2.The machine include bottle turn table,filling,capping, labeling,print date,Container machine etc.

3.It has intuitive and convenient operation, measuring accurate, positioning precision.

4.Fully in accordance with the GMP standard production and passed CE certification.

5.No bottle no filling.

Main Technical

| Filling volume | 250-2500ml |

| Filling Capacity | 2000-5000BPH |

| Filling Precision | 0-1% |

| Bottle type | plastic bottle,glass bottle or aluminum bottle |

| Voltage | 380V ,50HZ 3PHASE/220V 50HZ 1 PHASE |

| Power | 1.5KW |

| Net Weight | 1200KG |

| Dimension | 3500(L)×1500(W)×1900(H)mm |

Famous brand electrical part

| Parts Name | Brand | Country |

| Inverter | Mitsubishi | Japan |

| Air Switch | Schneider | France |

| Contactor | Schneider | France |

| Relay | Omron | Japan |

| Cylinder | AIRTAC | Taiwan |

| Touch screen | Mitsubishi | Japan |

| Touch screen | Mitsubishi | Japan |

MZH-FA 8Nozzles automatic liquid & paste filling machine (Piston type)

MACHINE FEATURES

◆For glass, ceramic bottle feeding bottle, bottle washing, filling, capping, a lock cover automatic productionLine.

◆Machine made of corrosion resistant stainless steel production,convenient cleaning and disinfection, comply with the relevant national food machineMachinery, food hygiene regulations and requirements.

◆The machine adopts imported infrared sensor, accurate position control.

◆Use imported PLC and 7 Inch Touch screen man-machine interface, production parameters of control, simple operation.

◆With height adjusting hand wheel,easy to adjust filling nozzle height, in order to adapt to the different height of products.

◆The organic glass cover design, to prevent impurities entering the filling materials, safety and health.

Reviews

There are no reviews yet.