Powder mixing machine

MZH series products has compact design, beautiful appearance, good sealing, stable performance, it is easy to operate and maintain and has high efficiency which is ideal equipment to deal with fine material.

Except for special type motor and some parts of them,other parts, which connect with material adopt high strength stainless steel.

It carries out heating treatment strengthen to pivotal dynamic and static refiner Disc so it has good anti-erosion and anti-wear properties and ensure processed material non-pollution, clean and pure.

Description

MZH Colloid Mill

Introduction:

MZH -Colloid mill particles toward a new type of processing equipment, applicable to all types of semifluid, fluid, homogeneous emulsion, emulsifying, mixing, crushing, etc..

Working Principle:

The working principle is Colloid mill shear, grinding and the role of high-speed mixing. Both rely on the tooth surface grinding of the relative motion, the base of a high-speed rotation, and the other stationary, so that between the tooth surface through the material under severe shear stress and friction, while in the high-frequency vibration, high-speed vortex such as the complexity of the role of power under effective material dispersion, emulsifying, crushing, homogeneous.

| Model | Emulsifying size (μm) the single cycle or more cycle | Adjust range(㎜) | Produce t / h according to materials changes | Power(kw) | Voltage(v) | Speed r/min | Grinding diameter (㎜) | Cooling water pipe diameter (inch) | Dimensions

L × W × H |

| MZH—50 | 5—40 | 1—0.01 | 0.01—0.2 | 1.1 | 380 | 2900 | ∮50 | ∮1/8" | 420×280×760 |

| MZH—80 | 3—40 | 1—0.01 | 0.3—1 | 3 | 380 | 2900 | ∮80 | ∮1/4" | 520×400×900 |

| MZH—100 | 2—40 | 1—0.01 | 0.5—2 | 5.5 | 380 | 2900 | ∮100 | ∮1/4" | 560×420×950 |

| MZH—120 | 2—40 | 1—0.01 | 0.7—3 | 7.5 | 380 | 2900 | ∮120 | ∮1/4" | 560×420×950 |

| MZH

—140 |

2—40 | 1—0.01 | 1—4 | 11 | 380 | 2900 | ∮140 | ∮1/4" | 600×450×1000 |

MZH- Horizontal sand mill

Use and performance

Three roller grinding machine is mainly used for all kinds of paint, printing ink, pigment, plastics, food and other paste slurry, but not grinding with acid-base components or sufficient to cause corrosion of roll of raw materials, mainly for paints, inks and other high viscosity material grinding and dispersion of the main equipment.

The machine machine in the horizontal direction through the arrangement of the three roller surface are jiga and different speed of friction to grinding, grinding materials as long as the general grinding quadratic can meet the requirements, difficult to research the material must be grinding times, in order to meet the requirements, fineness of finishing is generally up to 3-18 µ m a.s.l. (with the fineness of grind determination).

The main technical parameters which model do you select?

| Model | S65 | S150 | S200 | S260 | S315 | S405 | |

| Roller Diamter㎜ | Φ65 | Φ150 | Φ200 | Φ260 | Φ315 | Φ405 | |

| The working length of roller㎜ | 125 | 300 | 500 | 695 | 760 | 405 | |

| Roller speed

r.p.m |

Slow roll | 32 | 25.3 | 20 | 19.1 | 19 | 15 |

| Middle roll | 89 | 63.2 | 55 | 54.5 | 54 | 45 | |

| Fast roll | 250 | 152 | 155 | 155 | 155 | 135 | |

| Motor | Model | MS7144 | M100L1-4 | M112M-4 | M160M-6 | M160L-6 | M180M-6 |

| Power kw | 0.75 | 2.2 | 4 | 7.5 | 11 | 15 | |

| Speed r.p.m | 1400 | 1420 | 1420 | 970 | 970 | 970 | |

| Speed ratio | 1:2.8:7.8 | 1:2.5:6 | 1:2.8:8.1 | 1:2.8:8.1 | 1:2.8:8.1 | 1:3:9 | |

| Outline dimension

L*W*H |

420*400*440 | 820*800*920 | 1180*1120*980 | 1650*1350*1100 | 1720*1550*1180 | 2150*1980*1250 | |

| Weight KG | 80 | 500 | 750 | 2100 | 2800 | 5200 | |

III. Working principle

Work fast and slow and adjusted to proper position, start the machine, then will be added to the slurry of abrasive in between the roller and the slow roll copper knife, slurry after, the slow roll surface jiga, by in and bring fast and, by close to the surface of the out material scraper to be scraped, by blocking plate knife plate, into the bucket, which constitute the grinding process.

The structure of the machine

1.Machine parts

The body adopts casting, is composed of a base and an upper cover plate, the body around the rail surface in a horizontal direction with double row spherical roller bearings in the bearing seat, fast slow, one on each side, and the upper cover plate and connected together in the roller bearing seat is connected by bolts, the fast and slow roller bearing by adjusting screw and the action of the spring on the upper cover, do before and after the move, the bearing seat for supporting a slow, fast three roller, right end device of roller shaft has a cooling water pipe and water tank, the left drive gear, the lower part of the body which is arranged between the motor and the slow roll and roll two side by the vertical roller center equipped with copper with the knife feeding, fast and close to the front surface of the cylinder is equipped with a blade member with the material, which consists of three roller grinding machine.

2.Transmission part

The lower part of the machine seat is provided with a motor, through a triangle belt transmission, incoming fast and, by fast roller through the transmission gear to roll, and later transferred to the slow roll.

3.Roller

Roller is divided into fast, medium and slow the are composed of chilled alloy cast iron cast, at both ends of the pressure into a heat treatment of high-quality steel shaft head, the left shaft end is provided with a transmission gear, right shaft head intermediate through hole for the channel pore as a roller in cooling. Chilled rolls of not less than 15 mm, the hardness of not less than 70 shore hardness, surface precision grinding.

4.Feeding device

Into feeding device consists of a copper knife and copper knife holder, installed between the slow roll and roller ends, copper knife arc close to the slow, and two stick surface, to ensure that no material flow, using copper knife bracket bolt fixed on the body for adjusting the margins and disassembly and cleaning, copper knives should be often adjusted, provided for the roller surface close.

5.Cooling device

For the appropriate eliminating roller and the heat generated by friction after expansion effect of roller contact surface smooth, roller at the right spindle is equipped with cooling water pipes and pipe joints set in a rubber tube, through the water by the roller on the inner wall of the heat exchange, the original hole back into the water tank, into the sewer.

6.Discharging device

For a material discharging plate is installed on the body of a plate bracket, a plate with a blade, the plate adjusting screw makes the blade close to the fast and on the surface, edge fitting position should be is 5 mm higher than the roller center, to facilitate the smooth scraping through grinding attachment in fast and table on the surface of the material.

7.Pressure regulating device

Rotating the hand wheel, through the screw and the spring, to promote fast, slow roll along the guide rail before and after the move, in order to adjust the size of the grinding fineness.

MZH Series Colloid Mill

INTRODUCTION

The MZH series colloid mill is the micro-fabrication plant of wet materials. The structural type of the machine is the pioneer in domestic, which possesses the characteristics of advanced equipment, reliable performance, easy operation, balanced operation, small noise, easy maintenance, corrosion prevention, wide application, and complete varieties. Main technical specifications have reached the advanced level of the similar products both at home and abroad.

MZH series products has compact design, beautiful appearance, good sealing, stable performance, it is easy to operate and maintain and has high efficiency which is ideal equipment to deal with fine material. Except for special type motor and some parts of them,other parts, which connect with material adopt high strength stainless steel. It carries out heating treatment strengthen to pivotal dynamic and static refiner Disc so it has good anti-erosion and anti-wear properties and ensure processed material non-pollution, clean and pure.

SCOPE OF APPLICATION

Food-processing industry: juice, jam, beans, peanuts, cream, beverage, malted milk, egg yolk, ice-cream, etc.

Chemical industry concerned with products for daily use: grease, water quality, powder cream high-level cosmetics; shoe polish, tooth paste, soap, cleaning detergent, bath extract.

Chemical industry: lubricating grease, paints, coloring agents, emulsified asphalt, cementing compound, etc.

Other industries: plastic industry, pharmaceutical industry, textile industry, construction industry and coinage industry.

TECHNICAL SPECIFICATIONS

| Model | MZH50 | MZH80 | MZH100 | MZH100 | MZH400 | MZH400 | ||

| Emulsifying fineness(um) | ≤2 | ≤2 | ≤2 | ≤2 | ||||

| Capacity (T/h) | 0.01-0.05 | 0.5-1 | 0.5-3 | 0.5-4 | ||||

| Motor power(kw) | 0.75 | 1.1 | 3 | 4 | 5.5 | 7.5 | 7.5 | 1.1 |

| Motor voltage(V) | 220 | 380 | 380 | 380 | 380 | |||

| Motor speed(r/m) | 2900 | 2900 | 2900 | 2900 | ||||

| Outlet diameter | 5/8 | 1 | 1 | 11/2 | ||||

| Intel diameter | 11/4 | 2 | 21/2 | 21/2 | ||||

| Diameter of cooling pipe | 1/4 | 1/4 | 1/4 | |||||

| Weight | 40 | 130 | 200 | 180 | 240 | 200 | 400 | |

MZH-M 500L Horizontal Ribbon Powder Mixer

1.Characters

Full Stainless steel horizontal trough mixing machine suits for mixing powder or paste materials in Medicine, chemical and food industry.

2.Working principle:

Through Mechanical rotating, the machine’s “S” single impeller will rotate to make the materials Reciprocating flipping and get a homogeneous mixing. It is controlled by electric and able to set the time of mixing. When it’s up to the appointed time, the machine will stop., which can guarantee the quality of each mixing.

3.Specification:

| Model | MZH-M500L |

| Blades Type | s |

| Volume(L) | 500 |

| Rotate Speed(r/min) | <105° |

| Reversed Mix Angle | 1.5 |

| Mixing Motor (kw) | 5.5 |

| Batch Turning(kw) | 2.2 |

| Material | SUS304 |

| Dimension (mm) | 2150*860*1560 |

| Weight (kg) | 550 |

| Model | Volume

(M3) |

Loading weight

(Kg/time) |

Overall dimension

(L*W*H)(mm) |

Mixing

time (min) |

Speed

of stirring (r/min) |

Power

of motor (kw) |

Power of

feeding motor (kw) |

| 150 | 0.15 | 30 | 1360*540*1100 | 6-15 | 24 | 3 | 0.55 |

| 200 | 0.2 | 40 | 1460*600*1200 | 6-15 | 24 | 4 | 0.55 |

| 300 | 0.3 | 210 | 1900*750*1300 | 6-15 | 24 | 4 | 1.5 |

| 500 | 0.5 | 350 | 2150*860*1560 | 6-15 | 20 | 5.5 | 2.2 |

| 750 | 0.75 | 560 | 2300*1260*800 | 6-15 | 19 | 7.5 | 2.2 |

| 1000 | 1.0 | 780 | 2500*1300*860 | 6-15 | 19 | 7.5 | 3 |

| 1500 | 1.5 | 1150 | 2600*1400*940 | 6-15 | 14 | 11 | 3 |

| 2000 | 2.0 | 1500 | 3000*1500*1160 | 6-15 | 12 | 11 | 4 |

| 2500 | 2.5 | 2100 | 3500*1620*1250 | 8-20 | 12 | 15 | 4 |

| 3000 | 3.0 | 2250 | 3800*1780*1150 | 8-20 | 10 | 18.5 | 5.5 |

MZH-M2L,5L,10L Multidimensional movement replaceable bucket powder mixer

Overview and features of equipment:

This equipment is a new type of material mixing equipment, which is widely used in pharmaceutical, chemical, food, metallurgical, light industry and scientific research units. It is suitable for mixing of powdery or granular materials with better fluidity. This machine is supported by the universal joint of the active and passive axes in the direction of X, Y and Z. The material mixing barrel material from time to time, diffusion flow and shear flow, strengthen the effect of mixing, because the three-dimensional motion of mixing barrel, avoiding a general mixer generated by the centrifugal force of the material proportion of segregation and accumulation phenomenon, to ensure the efficiency of mixing material.

The main features of the machine are:

1, the mixing effect is high, the uniformity is about 99%, and the mixing time is short.

2, the loading coefficient is large, the loading coefficient of the general mixer is not more than 0.5, and the equipment can reach 0.8.

3, the structure of the equipment is compact, the transmission adopts frequency conversion and no pole speed regulation. It can be located at any position of the inlet and outlet through the reducer, and the operation is very convenient.

Equipment configuration: the organic seat of the machine, deceleration drive system, electrical control system, three-dimensional motion mechanism and mixing bucket and other components. This equipment is made of all stainless steel. It is convenient to clean, and the cylinder is all round arc transition, and it is closely polished to meet the requirements of GMP.

4, the biggest feature of this device is that a lot of different volume of the mixing barrel can be quickly replaced in the large mixing mother barrel, so that the materials of different varieties and weights can be evenly mixed, and all of them can meet the new version of the GMP code and the European Union certification standard.

6, the mixed mother barrel can also be directly mixed into the material mixture through the fast mounting lid, so that it can get a large capacity of mixing. It has many functions of one machine, convenient operation and low energy consumption.

7, the time relay is used to control the mixing time, and the mixing time is automatically stopped after setting the required mixing time.

- All the mixed barrels are polished with health level mirror surface, without dead angle, and meet the requirements of GMP.

III. Technical parameters:

Model: MZH-M multidimensional motion replaceable drum mixer

Loading weight (kg): (the quality of loading is related to the proportion of material)

2L For 0.5-1kg

5L For 1.25-2.5kg

8L For 2-4kg

(Main mixing cylinder)10L For 2.5-5kg

(main mixing cylinder) 10L

Spindle speed (r/min) 0~12 (variable frequency speed regulation)

Mixing time (min): 6~15 (depending on the material, the longest can be set for 99 minutes)

Motor power (kw): 1.1 (voltage 380V)

Size (mm): 900 x 600 x 550

Weight (kg):125

Main configuration list:

| No | Name | Material | Power | Remark |

| 1 | Reducer | WPDA80 60:1 | Hangzhou | |

| 2 | Electric machinery | 1.1KW | Zhongda motor | |

| 3 | principal axis | 45# | MIZIHO | |

| 4 | Bearing | Harbin Roll | ||

| 5 | Frame | Stainless steel 6.3# | MIZIHO | |

| 6 | Transmission sprocket | Forging | shanghai | |

| 7 | Variable frequency speed control controller | 0-12R/min | siemens | |

| 8 | An electric appliance | siemens | ||

| 9 | Time relay | Blending time control | Delixi electrical appliances | |

| 10 | Barrel | SUS304 δ=2.0 | Mirrow polish | MIZIHO |

| 11 | Sealing plate | SUS304 δ=1.0 | MIZIHO | |

| 12 | Arm | SUS304 | MIZIHO | |

| 13 | Feed port packages | Processing accessories | ||

| 14 | Discharging port packages | Processing accessories |

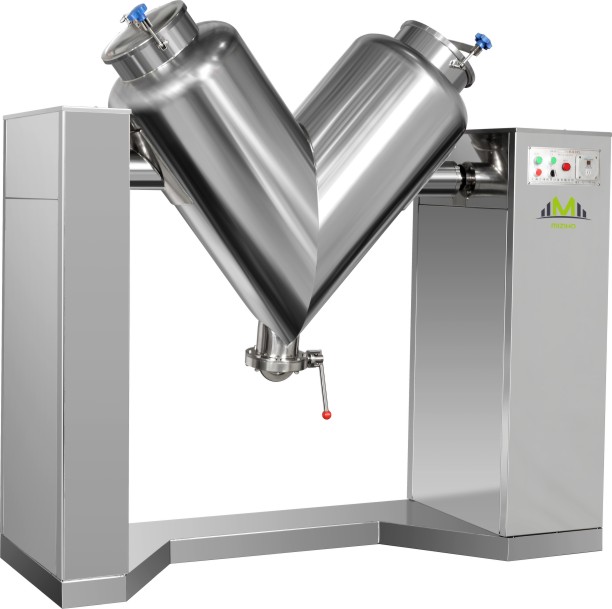

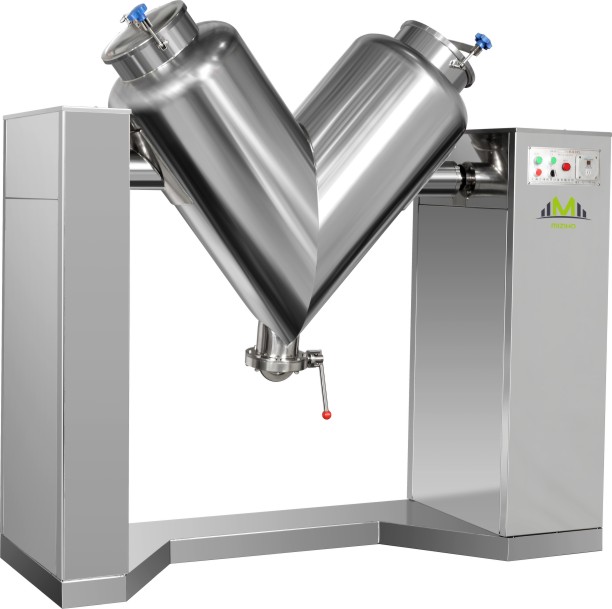

MZH-M100L V type powder mixer

Note: The mixer with SUS 316L for Medicine GMP grade factory.

Usage

The machine is widely used in the mixing of powder granular materials in pharmaceutical, chemical, feed and metallurgical industries.

Performance features

This machine is designed according to GMP specification, compact structure, easy operation, safe and efficient.. The special material can be used in vacuum feeding and sealing butterfly valve out of material, the implementation of no dust operation. There are two kinds of feeding methods, manual feeding and vacuum feeding, and the specific method is from the user.. The mixing machine has a unique four direction mixed movement track in the inner wall of the mixer, and the mixture has 99% directions. The mixing uniformity is, the mixing precision is high, and the speed is fast.

III.Technical parameters

| Model | Real Volume

kg |

L

(M) |

W (M) |

H (M) |

Discharge diameter mm | Discharge height mm | Rotary height mm | Mixing time min | Speed r/min | Motor power kw |

| MZH-0.3T | 120 | 2.37 | 1 | 1.27 | Ф150 | 600 | 1970 | 6~10 | 12 | 1.5 |

| MZH-0.5T | 200 | 2.6 | 1.1 | 1.43 | Ф150 | 580 | 2270 | 6~10 | 12 | 1.5 |

| MZH-1.0T | 400 | 3.09 | 1.35 | 1.55 | Ф150 | 550 | 1630 | 6~10 | 10 | 3.0 |

| MZH-1.5T | 600 | 3.44 | 1.4 | 1.65 | Ф200 | 580 | 2820 | 6~10 | 10 | 4.0 |

| MZH-2.0T | 800 | 3.75 | 1.45 | 1.75 | Ф200 | 580 | 3050 | 6~10 | 8 | 5.5 |

| MZH-2.5T | 1000 | 3.88 | 1.45 | 1.77 | Ф250 | 580 | 3150 | 6~10 | 8 | 5.5 |

| MZH-3.0T | 1200 | 3.97 | 1.48 | 1.87 | Ф250 | 600 | 3310 | 6~10 | 8 | 7.5 |

Reviews

There are no reviews yet.